Bambu Lab AMS is an intelligent system that requires maintenance to ensure stable feeding and automatic filament switching during printing. To help ease your purchasing decision, we have listed all the commonly needed maintenance parts and offered tiered discounts. You can find the purchase link on Spare Parts Page.

¶ PTFE Tube

PTFE tubes are consumables at risk of wear, as they may wear down over time due to friction with the filament. We recommend checking the PTFE tubes for wear during machine maintenance. If the tubes are worn and not replaced in time, this may lead to feeding failures and filament jams within the AMS. If needed, please refer to these tutorial videos on replacing PTFE tubes.

PTFE Tube Wear in AMS and Maintenance Recommendations | Bambu Lab Wiki

¶ Maintenance and Replacement Cycle for PTFE Tubes

Under normal usage conditions, the PTFE tubes should be replaced every two months to ensure unobstructed material movement in any usage scenario. When printing with abrasive materials (such as carbon fiber and glow-in-the-dark filament), the PTFE tubes should be checked and replaced monthly or whenever noticeable wear occurs. Regular maintenance can ensure the machine's smooth operation and extend the AMS's lifespan.

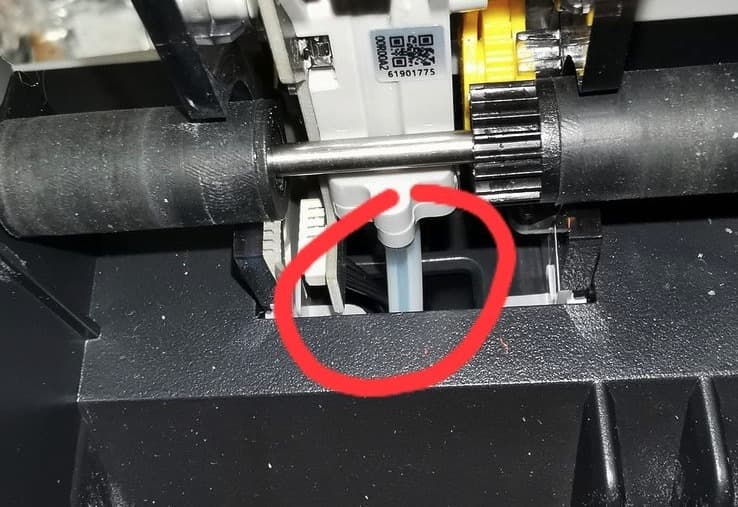

¶ Possible Damage Picutre of PTFE Tubes Inside the AMS

The picture below shows the possible damage locations of the internal PTFE tubes.

|

|

|

¶ Replacing the Internal PTFE Tubes of the AMS

¶ PTFE Tube Coupler

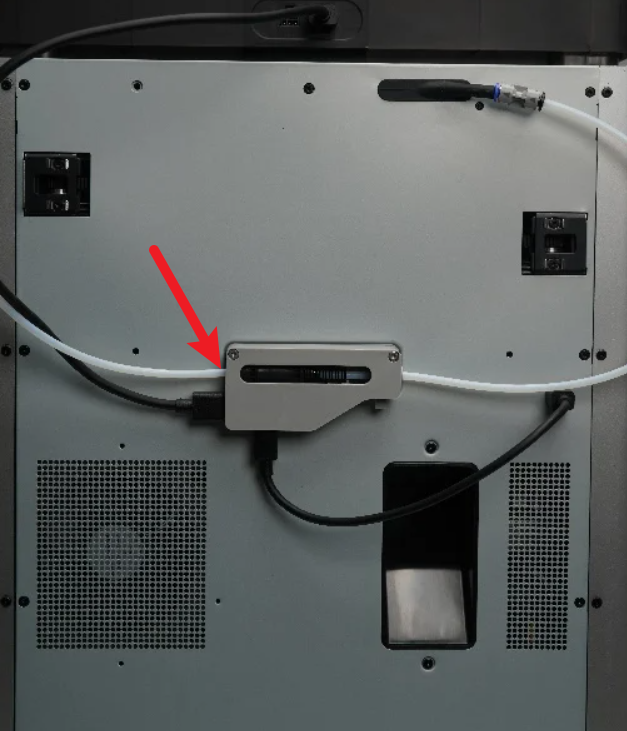

When you encounter the following situations, you can resolve the issue by replacing the pneumatic connector:

- The PTFE tube cannot be secured, such as when the PTFE tube cannot be fixed to the extruder.

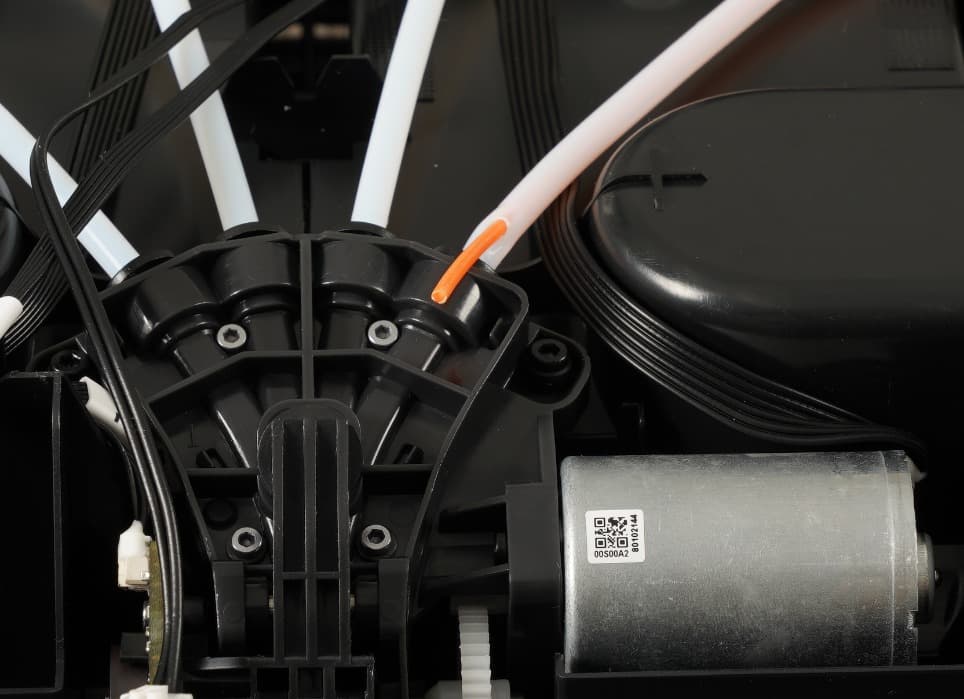

- The filament cannot pass through the pneumatic fittings, for example, when the filament cannot pass through the buffer (as shown in the image below, typically due to internal damage to the pneumatic fitting).

- The PTFE tube coupler is damaged.

Replacing the pneumatic connector (PTFE Tube Coupler) | Bambu Lab Wiki

¶ AMS feeding funnel

When the funnel-shaped feed inlet is severely worn and affects the loading and unloading process, such as causing overload on the assist motor or other HMS errors related to feeding and retracting, or if confirmed by after-sales personnel as a fault in the loading and unloading circuit board, it is recommended that you replace this component.

Replace the AMS feeding funnel | Bambu Lab Wiki

¶ AMS Active Support Shaft Assembly

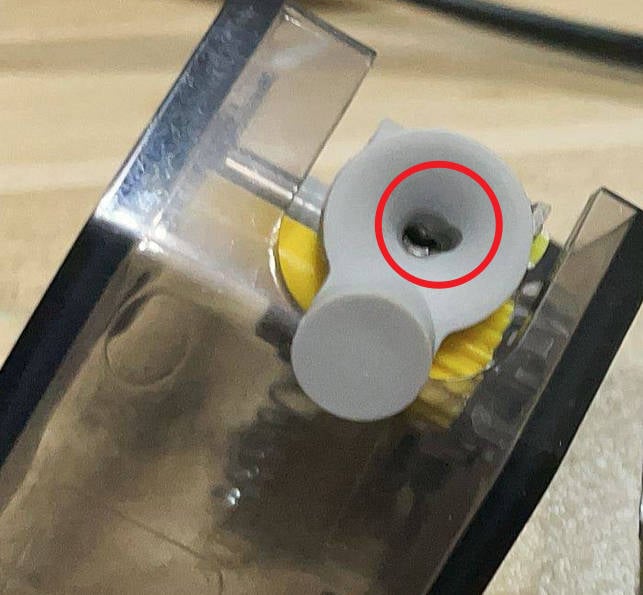

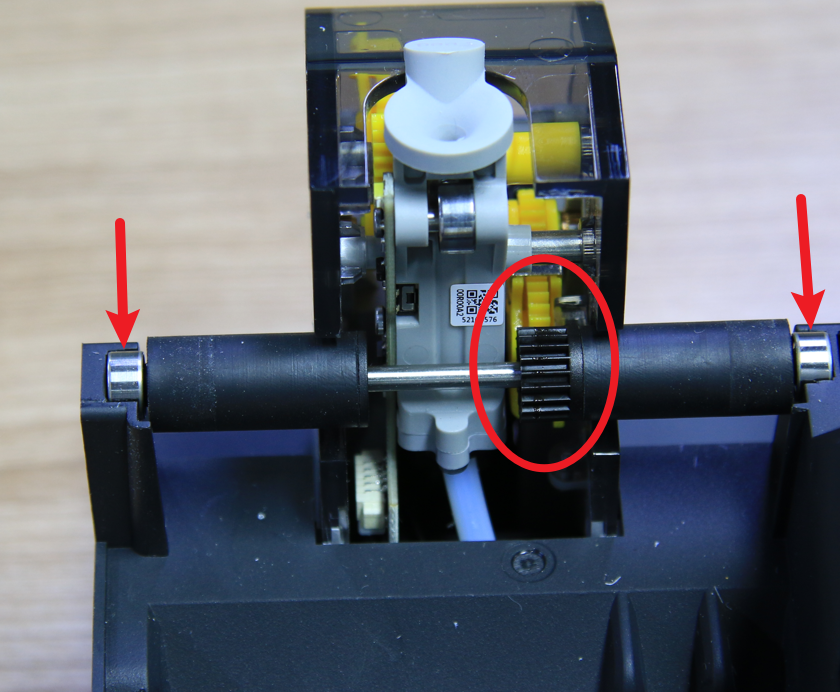

If the AMS Active Support Shaft Assembly shows obvious damage (at the three locations indicated in the image), or if it is not securely installed, it may result in poor engagement between the yellow gear of the loading and unloading assembly and the black gear of the support sleeve assembly, leading to feeding failures.

¶ Disassembling the AMS Active Support Shaft Assembly

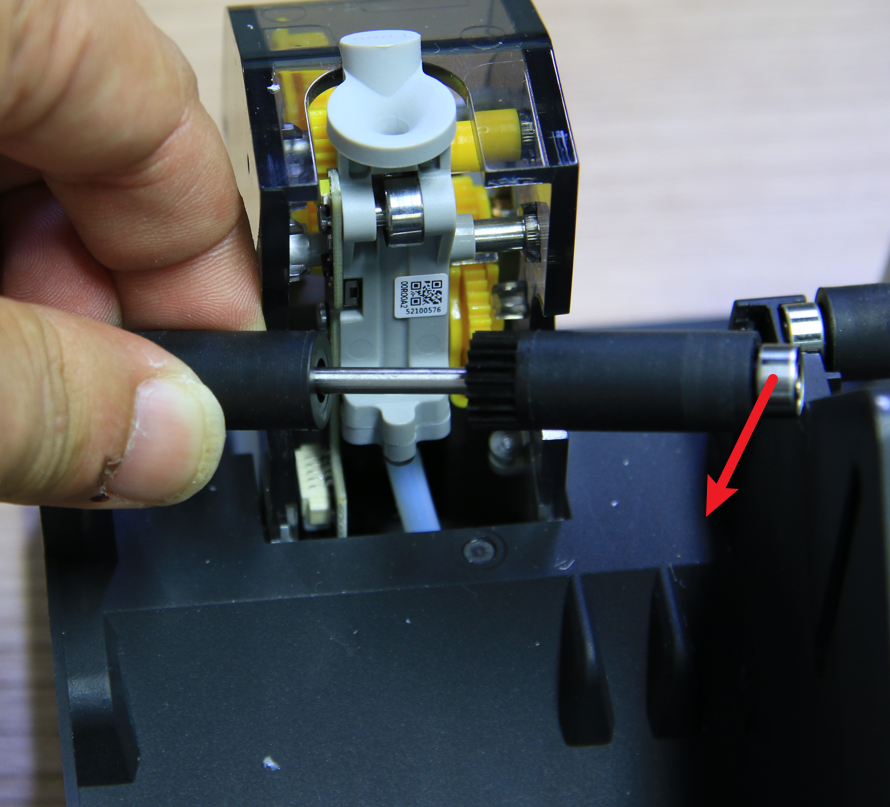

Remove the active support sleeve assembly in the following direction.

¶ Installing the Active Support Sleeve Assembly

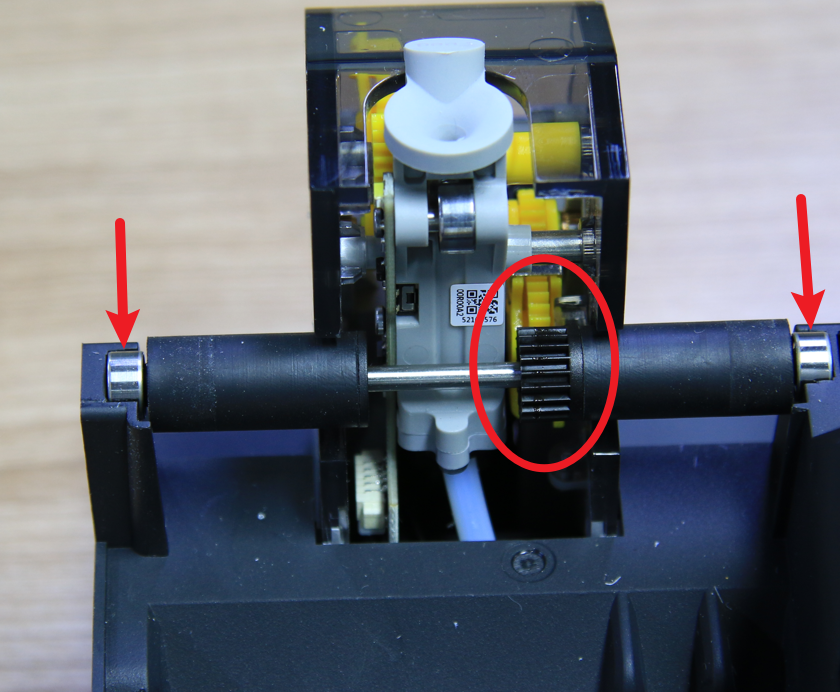

Install the active support sleeve assembly, ensuring that the gear positions are aligned to prevent incorrect installation.

¶ Desiccant for AMS

AMS has two compartments for storing desiccant bags to keep the internal air dry, thereby protecting your materials from moisture.

Replacing the desiccant | Bambu Lab Wiki

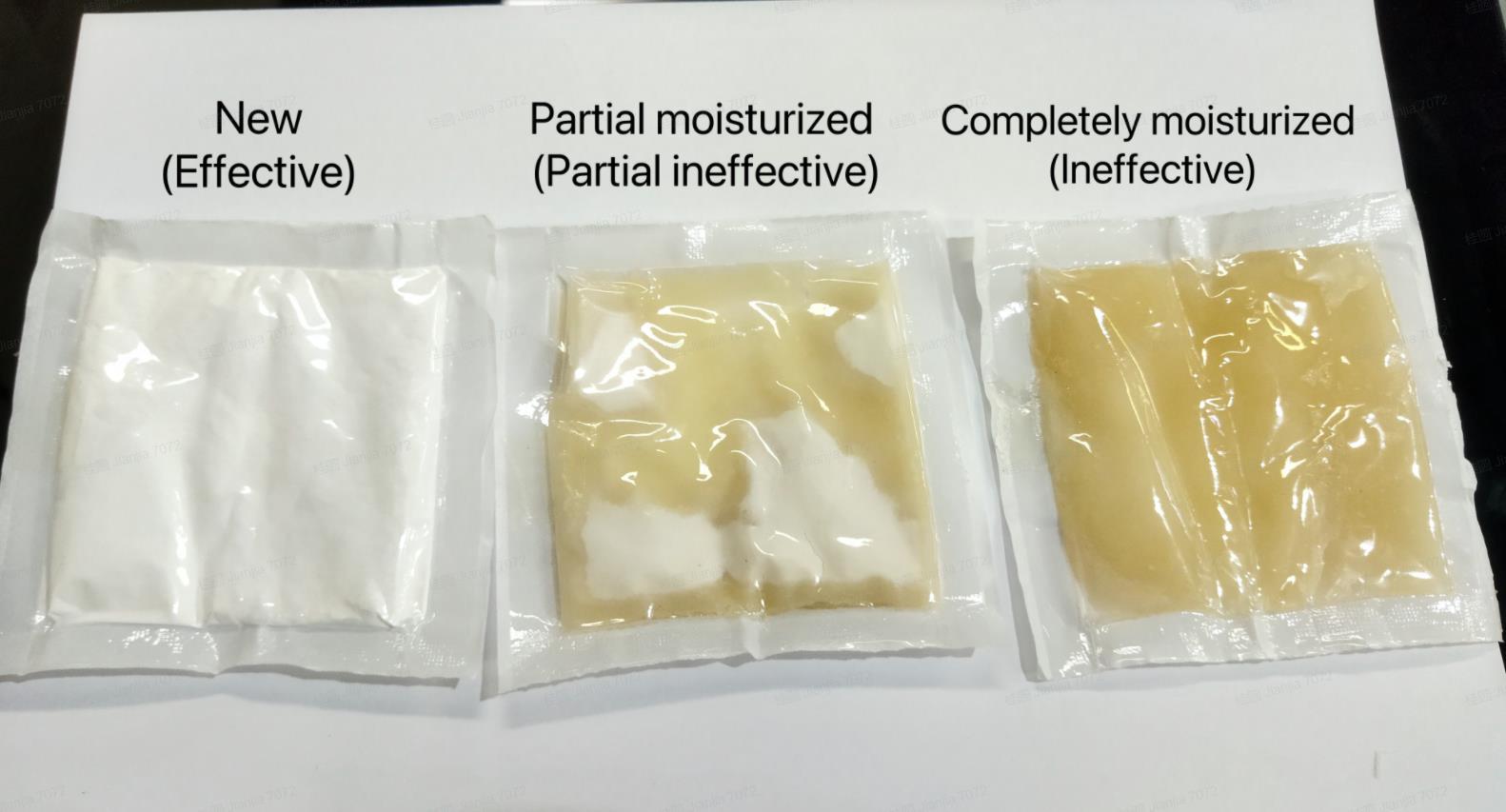

When you receive new desiccant bags, please remember to remove the outer packaging. Once the outer packaging is removed, the internal product will look like the left image in Figure 2 below:

Here is a picture of the actual packaging of the desiccant: