Hotend clogs are relatively common for FDM 3D printers and they can occur due to various reasons exemplified below:

- The filament used has a low glass transition temperature (gets softened when printing in an enclosure) - More information about heat creep available in this Wiki article.

- The filament has an inconsistent diameter, usually larger than the regular 1.75 mm getting stuck in the hotend.

- Debris present on the filament or inside the extruder has reached the hotend and clogged the nozzle completely, or partially

- Particulates from filament have blocked the nozzle tip of the hotend (common when printing with carbon fiber infused filament, glow in the dark or sparkling filament)

- When very different filament types were used and the previous filament was not purged completely (PLA and PC, ASA and TPU, etc)

¶ How to resolve a simple clog?

¶ Simple Clog / Partial Clog

A simple clog or partial clog is considered when the tip of the hotend is clogged with particulates inside the filament (carbon fiber, sparkling filament, etc). These particulates could be larger than the nozzle hole and will block it from being extruded.

Most of the time, these particulates could either clog the hotend completely, where there is no filament being extruded anymore, or a partial clog generated by debris on the filament which manifests itself by filament not flowing straight from the hotend and curling when extruding manually from the hotend.

When such a clog occurs the model is not printing as expected, with inconsistent extrusion leading to bad print quality.

It can also manifest itself with a badly calibrated K value for Flow Dynamics due to the inconsistent nozzle pressure and flow.

The easiest procedure to follow in this case is to try and dislodge the small piece blocking the hotend using the included pin you received with the printer.

Steps to unclog the hotend:

¶ 1. Set the hotend temperature to 250C

Using the on-screen menu, set the hotend temperature to 250℃.

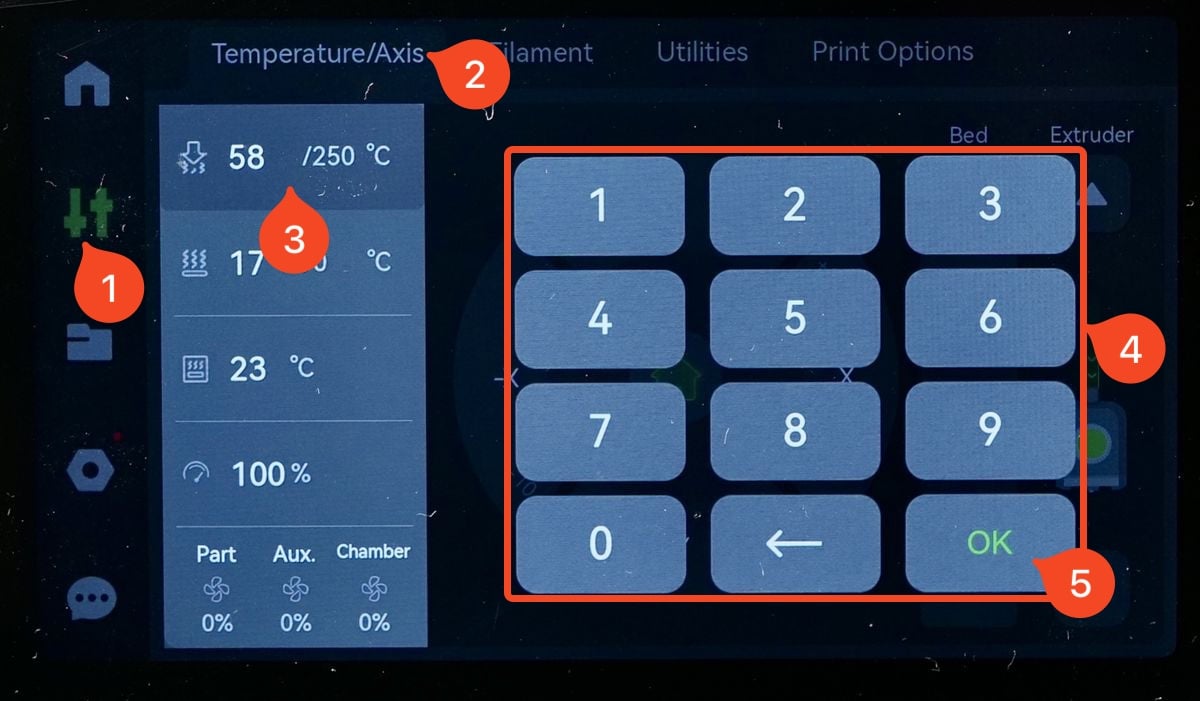

To do this, navigate to Settings → Temperature/Axis → Select the hotend temperature and enter the 250℃ value followed by the OK confirmation button.

|

|

This is the temperature that works best for PLA/PETG/TPU/ABS, or other filaments that can be printed at this temperature. For filaments that require a higher temperature to be printed, you can use a higher temperature.

¶ 2. Move the heatbed to a lower position

While the hotend reaches the set temperature, use the on-screen menu options to lower the heatbed to a position that allows you to easily work on the print head.

To do this, navigate to Settings → Temperature/Axis → Tap the -10 button multiple times until the heatbed reaches the middle section of the printer.

|

|

¶ 3. Insert the pin through the nozzle tip (Skip this step for 0.2mm nozzles)

With the hotend at temperature, insert the pin inside the nozzle tip, and move the pin through the nozzle a few times, to dislodge any debris that could be present in the hotend.

Ensure that you don't push the pin too far in the hotend, as you might push the molten filament higher, leading to a harder-to-remove clog.

The red line in the image below shows how far you should push the pin.

Caution! We recommend using heat-protective gloves for this operation. The molten filament can drip on your fingers causing burns.

¶ 4. Confirm the nozzle is flowing correctly

After moving the pin through the nozzle tip a few times, remove the pin and extrude some filament using the on-screen buttons. The filament should flow in a straight line and should not curl during extrusion, as shown in the image below.

If the filament flows in a straight line, the hotend should be successfully unclogged.

¶ Hot hex wrench unclogging method

A common clog that occurs on X1/P1 series is the filament getting stuck inside the hotend due to heat creep issues. This phenomenon was covered in detail in this article, and we recommend reading it to understand how to avoid this type of clog.

When this happens, the filament swells inside the hotend and cannot be easily removed. In the pictures below, you can see an example of filament getting stuck inside the hotend

Fortunately, there is a relatively easy method to clean the filament inside the hotend with a Allen key and a lighter.

Parts Required:

- 1.5mm hex wrench

- Lighter

¶ 1. Remove the hotend from the print head

The first step in unclogging the hotend is to remove it from the print head. Carefully remove the three wires from the extruder connection board, by pulling on the plastic connectors.

Avoid pulling on the wires, as there is a high chance to damage the wires and/or the connection board.

Pay special attention to the thermistor connector (nr. 3), as it has a plastic release clip in the top.

You need to press on it to release it, before pulling the connector out

After the wires are disconnected, you can remove the two hotend screws holding it in place to completely remove it from the print head.

¶ 2. Heat the hex wrench and push it inside the hotend

Caution! We recommend using heat-protective gloves for this operation. The molten filament can drip on your fingers causing burns.

Now that the hotend is completely removed from the printer, we can proceed with unclogging it.

Take the 1.5mm hex wrench and use the lighter to heat it for 10-15 seconds. When the tip of the hex wrench starts to change color, it is ready.

While the tip of the wrench is hot, quickly push it in the hotend, through the top end of the heatsink.

The hot wrench will go inside the filament, as shown in the image below. Then, wait for about 30 seconds for the hex wrench to get cold.

¶ 3. Heat the tip of the hotend and pull filament clog

The hex wrench is now stuck inside the hotend, with filament around it. To remove the wrench with the filament clogging the hotend, you will need to heat the tip of the hotend.

First, remove the silicone sock of the hotend, then apply heat using the lighter to the tip of the nozzle for about 20 seconds (when using a regular lighter).

Caution!: Avoid heating the nozzle for a longer period or using a high power butane torch. A regular gas lighter is recommended.

The hot side of the nozzle needs to only be hot enough so you can remove the hex tool with the filament.

Overheating the nozzle can lead to the filament dripping or popping from the tip. Carefully follow the instructions and don't point the nozzle tip towards you when doing this procedure.

After heating the tip of the nozzle for 20 seconds, you can pull slowly on the wrench. You will notice that the filament comes out from the hotend in a single piece, clearing the clog.

You can now follow step 1 in reverse, to re-install the hotend back to the print head.

Don't forget to carefully arrange the hotend wires around the extruder. If they are not correctly arranged, they could push against the front cover causing failures during printing.

¶ Alternative cleaning method (video)

We also have a video available showing you how to do a similar procedure that does not require the hotend to be removed.

If you follow this video guide, please make sure to keep the hotend stable during this operation.

There is a higher chance to damage the hotend wires or the connection board, if the hotend is not kept stable.

¶ Cold Pull Method

After every cleaning procedure shown in this article, we strongly recommend performing a cold pull procedure.

A cold pull will ensure the inside of the hotend is clean, and will minimize the chances for any printing issues caused by the hotend.

¶ 1. Remove the print head cover and the PTFE tube

The first step for a cold pull is to remove the front cover of the print head and the PTFE tube.

With the front cover set to the side, loosen the screws next to the PTFE support. (do not remove)

Finally, to remove the PTFE tube you need to push on the PTFE support, then pull on the tube upwards, as shown in the image below:

You can now start the cold pull procedure

¶ 2. Set the hotend temperature then load filament

This step depends on the filament used to perform the cold pull procedure. The most common filament used for cold pulls is PLA, which requires the hotend to be set at 220C and we will use this as an example.

Using the screen, navigate to Settings → Temperature/Axis → Select the hotend temperature and enter the 220C value followed by the OK confirmation button.

|

|

After the hotend reaches 220C, push filament in the top of the extruder as shown in the image below, then use the extrude button on the screen to feed it until you see filament being extruded from the tip of the nozzle.

¶ 3. Set the hotend temperature to 100C and wait

With the filament loaded in the hotend, set the temperature to 100C and wait for the hotend to reach the desired temperature.

The 100C is selected to ensure the filament is just soft enough to be pulled away from the hotend, but still not soft enough to get damaged during the operation.

¶ 4. Retract the filament

As soon as the hotend reaches 100C, use the retract button on the screen to start pulling the filament.

We recommend also pulling on the end of the filament to help the extruder.

DO NOT pull hard, as you only want to help the extruder, not to pull against the gears and motor.

Usually, it is recommended to perform this operation a few times, until the filament you are pulling from the hotend is clean and free from any debris.

¶ 5. Re-install the PTFE tube and support

To re-install the PTFE tube you simply need to push it back in the extruder filament sensor.

Then, make sure that you raise the PTFE tube support piece as high as possible, before tightening it in place.

This step is important, as it ensures the filament path and less filament resistance towards the extruder.

¶ Cold Pull Video Guide

We also have a video that shows the entire procedure for performing a cold pull to clean the hotend.

¶ End Notes

We hope that the detailed guide we shared with you was helpful and informative.

We want to ensure that you can perform it safely and effectively. If you have any concerns or questions regarding the process described in this article, we encourage you to reach out to our friendly customer service team before starting the operation. Our team is always ready to help you and answer any questions you may have.

Click here to open a new ticket in our Support Page.

We will do our best to respond promptly and provide you with the assistance you need.