¶ Version 01.04.00.00

¶ New Features

1. Added support for offline Firmware update from MicroSD card. How to: Firmware Upgrade via microSD Card - A1.

2. Added support for filament editing while printing.

- Only the filament that is not in use can be edited.

- The printer will automatically remap the filament backup according to the new filament settings. Know more about filament backup. AMS main functions and workflow introduction.

3. Added support for Automatic Flow Dynamics Calibration for multiple filaments via Bambu Studio. For more details on “Flow Dynamics Calibration”, please refer to: Flow Dynamics Calibration.

4. Added support for filament verification for “Reducing purging through retracting filament” function.

- A long retraction during filament change can significantly reduce the purge volume, but it may cause clogging when the filaments assigned in the sliced file do not completely match the actual filaments in use. The filament verification function will verify the filaments match before performing retraction.

- This function needs to be used with the slice files generated by Bambu studio v01.09.00.67 and above. For more information about the “Reducing purging through retracting filament” function, please refer to: Bambu Studio 1.9.1 Release Notes.

5. Added interruption button when load/unloading filaments when not printing.

¶ Feature Optimizations

- Optimized the temperature setting input UI of the nozzle and heatbed to a digital keypad.

- Optimized the heatbed parking location when pausing the print for the user to conveniently operate the touch screen.

- Gradually increase the heatbed moving speed when restarting a paused print for increased safety.

- Added a notification queue “Green dot” to notify for new firmware updates.

- Pause print if abnormal bed-leveling data exceed the threshold. This helps protect the buildplate from unwanted damage.

¶ Bug Fixes

- Fixed a low chance flow calibration K factor defect.

- Fixed a low chance issue of the AMS lite not being recognized by the printer.

- Fixed several copy & UI problems.

- Fixed a HMS refreshing problem.

- Fixed a faulty reboot problem after filament presets editing.

¶ Version 01.03.01.02

¶ Improvement

- Improved printing stability.

- Optimized read-and-write compatibility for Micro SD cards.

¶ Version 01.03.01.00 (20240722)

¶ Improvement

Improved system stability.

¶ Bug Fixes

- Fixed the issue where the printer did not report an error for homing failure.

- Fixed the intermittent failure to continue printing after power loss.

- Fixed the intermittent time synchronization failure.

- Fixed the intermittent manual calibration failure.

- Fixed the issue where there was a small chance the K factor from flow dynamics calibration was not effective.

¶ Version 01.03.00.00 (20240612)

¶ New Features

- Third-party filament support

- Users can create and manage custom filament profiles in Studio. These custom filaments can then be selected in Device filament slots

- Expedite partial bed-leveling (in conjunction with Bambu Studio V1.9 and above)

- Run bed-leveling according to the outer contour of the sliced models, instead of the whole build plate area.

- Added notification sound when the printer is working abnormally

- Improved color display for gradient and dual-color filaments

- Auto-save the manual flow calibration parameters

- Auto-save the manual flow calibration parameters

- Support creating & managing new PA parameters

- Support setting PA configuration files on the filament settings page

- Non-LAN binding via PIN code on the studio side (in conjunction with Bambu Studio v01.9.2 and above)

- Users can bind A1 devices to the computer that is not on the same local area network (LAN) using a PIN code on the studio side

- Added low ambient temperature protection, prohibited operation if the ambient temperature is below -5 ℃ 【A1 only】

¶ Feature Optimizations

- Improved the print time calculation logic, supported inclusion of abnormal stop time.

- Optimized the wording and interface in error code pop-ups.

- Optimized nozzle clumping detection logic.

- Added UI interface explanation of the impacts and precautions of nozzle clumping detection.

¶ Bug Fixes

- Fixed the lack of notification on Handy when the AMS causes a print pause.

- Fixed the issue of switching ON/OFF delay video gradients during the printing process.

- Fixed the intermittent homing failed issue.

- Fixed the false alarm of nozzle clumping detection.

¶ Version 01.02.02.00 (20240515)

¶ Improvement

- Improved printing stability.

¶ Version 01.02.01.00 (20240326)

This firmware update optimized the heatbed temperature failsafe.

¶ Feature Optimizations

Optimized the heatbed temperature threshold to reduce false alarms.

¶ Version 01.02.00.01 (20240206)

Version 01.02.00.01 firmware introduces several convenient features designed to enhance the user experience. The Build Plate Detection feature eliminates the possibility of human error by preventing a print from starting without the build plate in place. Similarly, the Air Printing Detection feature halts your print upon detecting extrusion issues, thereby conserving filament and saving time.

Below, you'll find some of the key updates that Version 1.2 brings:

- Implemented the "Air Printing" detection feature to identify extrusion issues such as clogging and filament grinding.

- Introduced the Build Plate Detection feature to ensure that the build plate is properly positioned before initiating each print job.

- Introduced 'Nozzle Clumping Detection' which can automatically detect filament clumping on the nozzle.

- Supports SD card remote browsing for time-lapses and models.

For more detailed information about each of these new features, continue reading below:

¶ New Features

¶ "Air Printing" Detection (in conjunction with AMS lite)

"Air Printing" occurs when filament flow either stops or slows down mid-print, causing the toolhead to move without extruding filament properly. If not detected promptly, this issue can result in a significant waste of print time and filament.

The "Air Printing" detection system will closely monitor the odometer reading of AMS lite. If its count does not match the expected feeding length in the Gcode command, which indicates potential slipping in the extruder gear, signaling issues like clogging or filament grinding. In such cases, the "Air Printing" detection system will pause the print and display a warning message.

Note: This feature is optimized for hotends of 0.4 mm and larger sizes. The 0.2 mm hotend is currently not optimized, but we are actively working on enhancing its compatibility.

¶ Build Plate Detection(Bambu Studio version≥1.8.4.51)

Forgetting to place the build plate is a common oversight among beginners. Printing directly on the heatbed can potentially damage your printer. The Build Plate Detection feature addresses this issue by implementing a verification procedure before each print, ensuring that a build plate is correctly installed on the heatbed.

This feature works on the official build plate (or build plate with exact same shape as the official build plate) only.

¶ Nozzle Clumping Detection

By probing the nozzle to the edge of the build plate, A1 can automatically detect filament clumping around the nozzle. The detection feature is ON by default runs checking every 8 grams of filament usage, and can be turned OFF in the Print Options menu.

¶ SD card remote browsing

To improve the user experience with the printer, we introduced file management in Bambu Studio for files on MicroSD cards. You can now delete and print items, and manage timelapses from the available files on the MicroSD card right from Bambu Studio.

¶ Feature Optimizations

- Added filament color settings based on AMS's existing colors.

- Optimized the UI of the Settings menu.

- Improved flow calibration for the 0.2 mm hotend.

- Refine the log system and remove all debug logs that are not necessary for end-users. Thanks to X1plus team's feedback.

- Added SD card remote browsing support for time-lapse videos and models. (in conjunction with Bambu Studio V1.8.1)

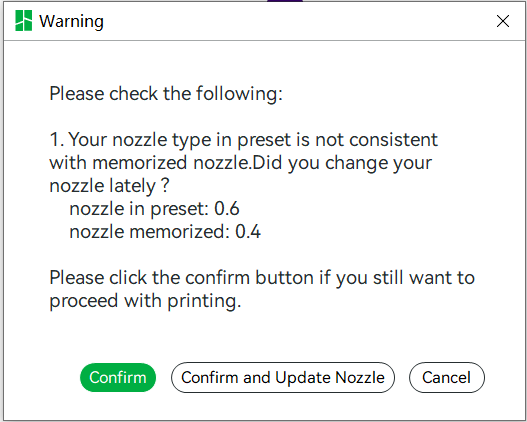

- Automatic nozzle size and type verification in conjunction with Bambu Studio(Version 1.8.3.89 and up) . The nozzle type can be set on the maintenance page in the settings menu.

¶ Bug Fixes

- Finalized the printer model check for inbound 3MF files.

- Resolved the false alarm related to hotend temperature.

- Addressed the intermittent missing start button issue in the calibration UI.

- Fixed intermittent errors associated with the object-skipping feature.

- Resolved intermittent download issues caused by lengthy file names.

- Refined the UI wording for improved clarity.

- Fixed a UI glitch observed when initiating a calibration from Studio/Handy.

¶ Remaining Bugs

- Intermittent color mismatches when using AMS colors to edit non-Bambu filaments.

- Toolhead erroneously returns to the printing area after canceling the print due to filament runout or filament change error.

- Intermittent power loss recovery failure.

¶ Version 01.01.01.00 (2023.12.22)

With the release of version 01.01.01.00, our team implemented some bug fixes for the A1.

¶ Bug Fixes

- Fixed the issue of incorrectly displaying “140%” speed value in Sport mode.

- Fixed the issue of incorrectly displaying the time required for auto bed leveling calibration.

- Fixed the issue of incorrect page number display within the settings menu interface.