¶ What it is

MC stands for Machine Controller, Which is the unit that controls all the moving parts of the printer.

¶ When to use this guide

The board would need to be replaced in case of a failure where the machine would fail to function mechanically in cases of physical damage or board burnout. In some cases the log file would be needed to determine if any issue with the machine originates from the MC board

¶ Tools and materials needed

- New MC board

- H1.5 & H2.0 Allen key

- Tweezers

- Hair Dryer

- Silicon glue

¶ Safety warning and Machine state before starting operation

Prior to commencing with the process in this guide, please make sure the machine is switched off and that the AMS along with the PTFE tube and filament buffer are removed

¶ Operation guide

¶ Step 1 - (Disassembly) Remove screws

Undo the screws at the back of the printer as marked below. There are a total of 14 screws to undo, 10 of them in the first image and 4 in the second image as shown below.

|

|

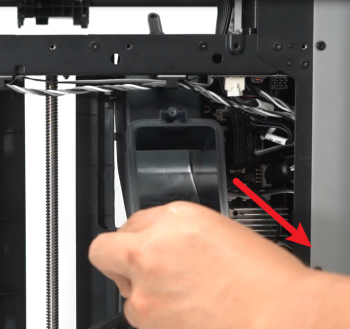

¶ Step 2 - Removing the rear cover

To remove the rear cover, it is important to first pull the left side so that the left belt tension port doesn't get in the way, followed by the right side. Push the PTFE tube outlet inwards to free it from the cover.

|

|

¶ Step 3 - Removing the excess chute

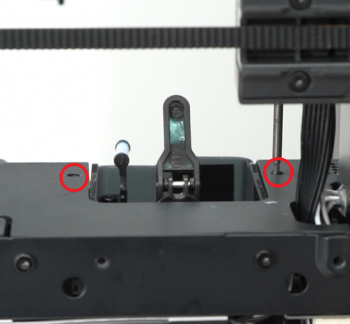

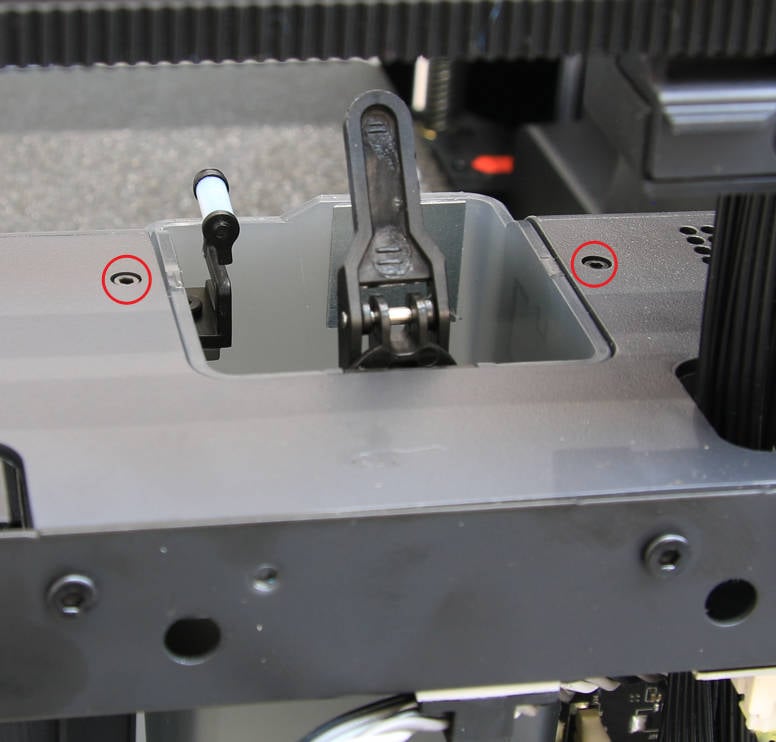

Undo the screws located at each side of the excess chute. once done, take out the excess chute. Some printers have three screws to secure the excess chute, while some only have two; please refer to your unique situation.

Note: For some versions, the heat bed cables are fixed to the bottom of the excess chute with a buckle, do not use too much force when taking off the excess chute.

Two screws case:

|

|

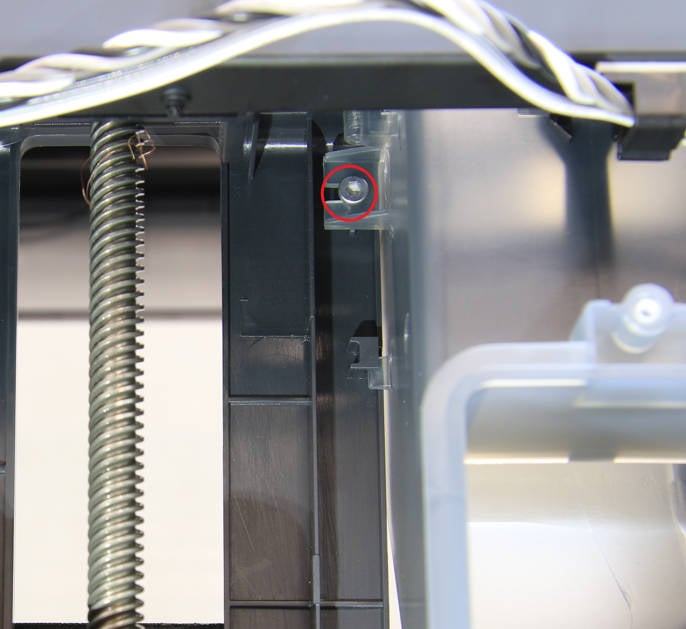

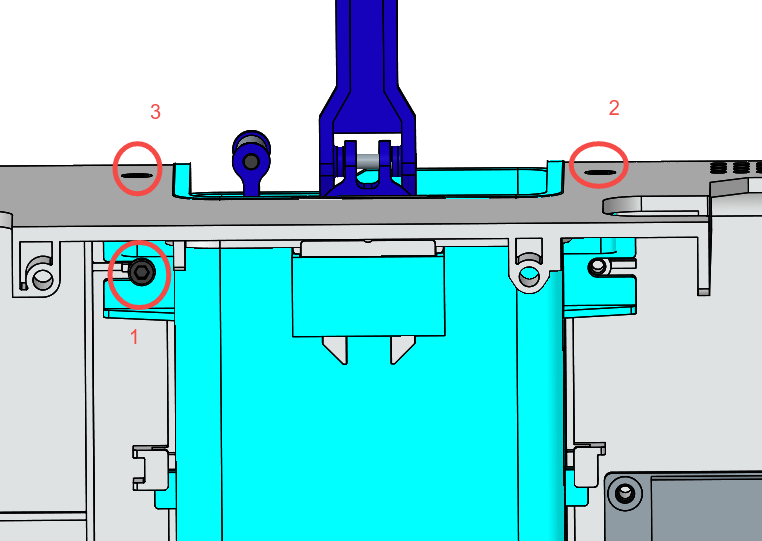

Three screws case:

|

|

|

¶ Step 4 - Disconnecting cables

NOTE: Prior to proceeding with this step, it is recommended to mark all cables and take photos in order to remember their location when reattaching them to the new MC board.

Disconnect all cables from the MC board, and disconnect all the cables on the MC board. You will need a hair dryer to soften the silicon glue around the heatbed wire in order to remove it.

|

|

¶ Step 5 - Removing the MC board

Undo the 4 screws holding the MC board in place, and then remove the board itself.

Note: The bottom right-hand corner screw also holds the “ground” connector to it

|

|

¶ Step 6 - (Assembly) Installing the MC board

Place the new MC Board in the same location and orientation as the previous one and use the 4 screws Install the MC board. Remember to attach the “ground” cable to the bottom right-hand side screw

|

|

¶ Step 7 - Connecting the cables

Connect all the cables to the MC board referencing the photos or marking you have done in the disassembly stage. On the heat bed cable, place a dab of silicone glue to secure it in and wait 30 minutes for the glue to completely dry.

| NO. | Connect object | NO. | Connect object | NO. | Connect object |

|---|---|---|---|---|---|

| 1 | Motor Z | 5 | Auxiliary part cooling fan | 9 | AP main board (Power cable) |

| 2 | The right motor (view from the rear) | 6 | MC board fan | 10 | AP main board (Communication cable ) |

| 3 | The left motor (view from the rear) | 7 | MC board to AC board connecting cable | 11 | Heat bed (Communication cable) |

| 4 | The chamber temperature regulator fan | 8 | AMS interface board |

¶ Step 8 - Installing the excess chute

Install the excess chute by sliding it back in its position, pay attention to the protruding tabs on both sides of the chute. Finally, secure it in place with 2 screws at each side of the top of the chute.

|

|

¶ Step 9 - Installing the rear cover

First, pass through the tube bracket and then secure the right side of the back cover past the right belt tensioner as shown below, followed by the left belt tensioner.

|

|

¶ Step 10 - Lock screws

Screw the back panel back on. Take note of the different types of screws (10 and 4) used as pointed out previously

|

|

|

¶ How to verify completion/success

Connect the power cord and turn on the power.

For X1 and X1-C (without AMS), Run a Device self-test operation as shown below and if no errors occur, the replacement was successful.

For X1-C combo (with AMS), you also need to install the AMS buffer, connect the AMS and run the filament loading procedure on the display menu. if no errors occur, the replacement was successful.

Should you come across any issues, first retrace your steps and check all connections to try again. If problems persist, contact the service team for further assistance.