¶ Phenomenon:

1. Excessive movement of the screw rod in the Z direction;

/x1/troubleshooting/loosen-belt-wheel/loose_lead_screw.mp4

2. There is a deviation in the height of the three Z-axis sliders, which may cause the heat bed to fail when homing.

¶ Causes & Solutions:

- The Z-axis timing pulley is loose and needs to be re-locked;

- During the Z-axis movement, external forces or foreign objects interfere, causing the Z-belt to slip, resulting in the three Z-sliders being out of sync. At this point, it is necessary to redo the consistency adjustment of the Z-axis sliders.

¶ Tools and materials needed

- H1.5 /2.0 hex key;

- Scraper or cutting pliers;

- Hammer.

¶ Safety Warning

IMPORTANT!

It's crucial to power off the printer before performing any maintenance work on the printer and its electronics, including tool head wires, because leaving the printer on while conducting such tasks can cause a short circuit, which can lead to additional electronic damage and safety hazards.

When you perform maintenane or troubleshooting on the printer, you may be required to disassemble some parts, including the hotend. This process can expose wires and electrical components that could potentially short circuit if they come into contact with each other or with other metal or electronic components while the printer is still on. This can damage the electronics of the printer and cause further damage.

Therefore, it's essential to switch off the printer and disconnect it from the power source before doing any maintenance work. This will prevent any short circuits or damage to the printer's electronics. By doing so, you can avoid potential damage to the printer's electronic components and ensure that the maintenance work is performed safely and effectively.

If you have any concerns or questions about following this guide, open a new ticket in our Support Page and we will do our best to respond promptly and provide you with the assistance you need.

¶ Operation (1) Repair of Loose Screw Rod

Important!

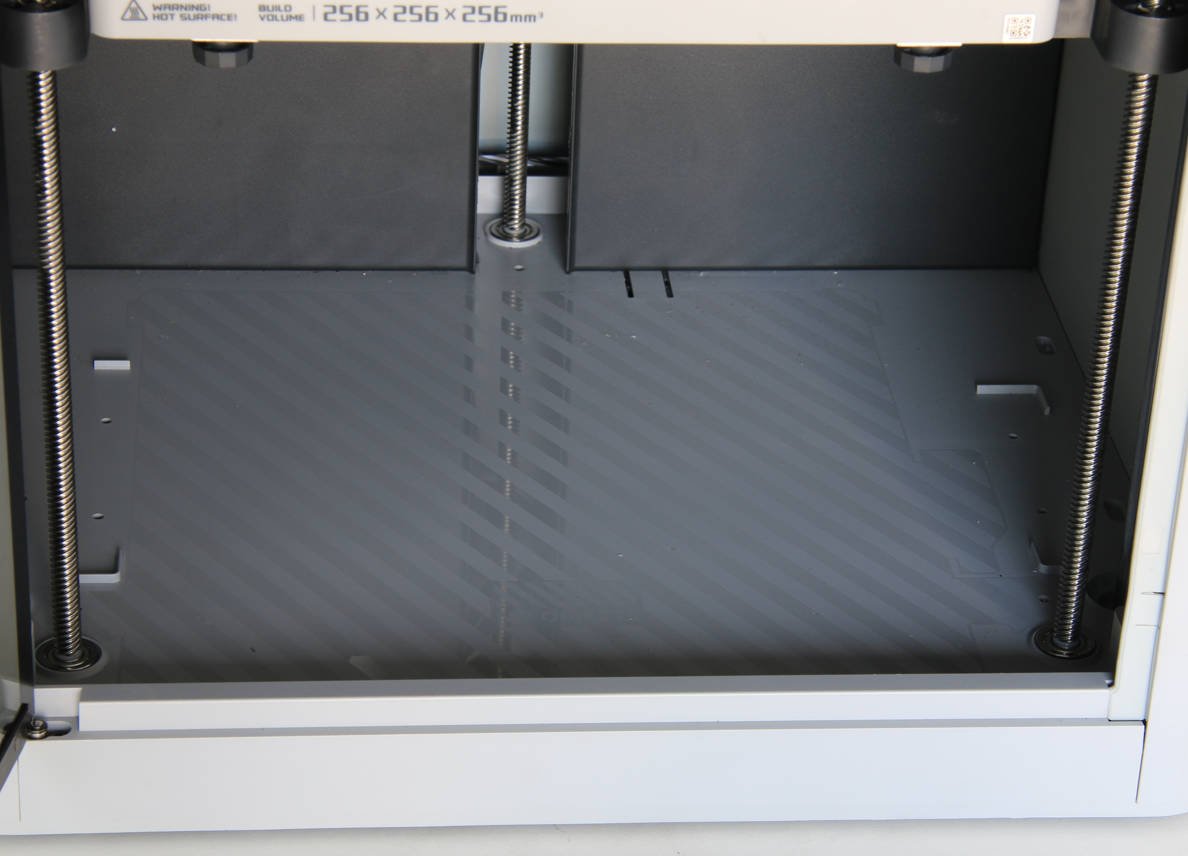

Before starting the operation, ensure that the heatbed is lowered to the bottom position of the printer.

¶ Step 1- Remove the glass cover and display screen

Disconnect the power cord, and remove the glass cover and display screen.

¶ Step 2 - Put the printer upside down

Turn the printer upside down to expose the bottom timing pulley.

¶ Step 3 - Unlock the Z timing pulley

|

Locate the loose Z timing pulley and use a scraper or pliers to remove the AB glue on the timing pulley.  |

Loosen the 2 timing pulley fixing screws to make the timing pulley move up and down along the Z direction.  |

If the timing pulley is stuck, you can use a hammer to tap the bottom of the screw rod so that there is a looseness between the screw rod and the timing pulley.

¶ Step 4 - Reset the timing pulley

|

Grasp the screw rod with one hand and push it toward the base of the printer, hold the timing pulley with the other hand, and force it in the opposite direction to reset the timing pulley.  |

In general, a small part of the screw rod should be exposed outside the synchronous pulley. Pull the timing pulley along the Z direction to confirm that it is not loose.  |

¶ Step 5 - Lock the timing pulley

Tighten the two fixing screws of the synchronous pulley. If possible, re-apply AB glue on the original position for reinforcement.

¶ Step 6 - Tensioning the Z timing belt

|

Loosen the Z tensioner screw.  |

Pull the belt back and forth 3 to 5 times by hand and re-lock the tensioner screw.  |

¶ Step 7 - Put the printer upright and install the screen

Put the printer upright, connect the screen, and reinstall the upper glass plate.

¶ Operation (2) Position adjustment of the Z-axis sliders

¶ Step 1- Remove the glass cover and display screen

Disconnect the power cord and remove the glass cover and display screen.

¶ Step 2 - Clean the base of the printer

|

Remove foreign objects from the base of the printer  |

Especially make sure to check for residue under the polished rod.  |

¶ Step 3 - Lock the 3 Z sliders

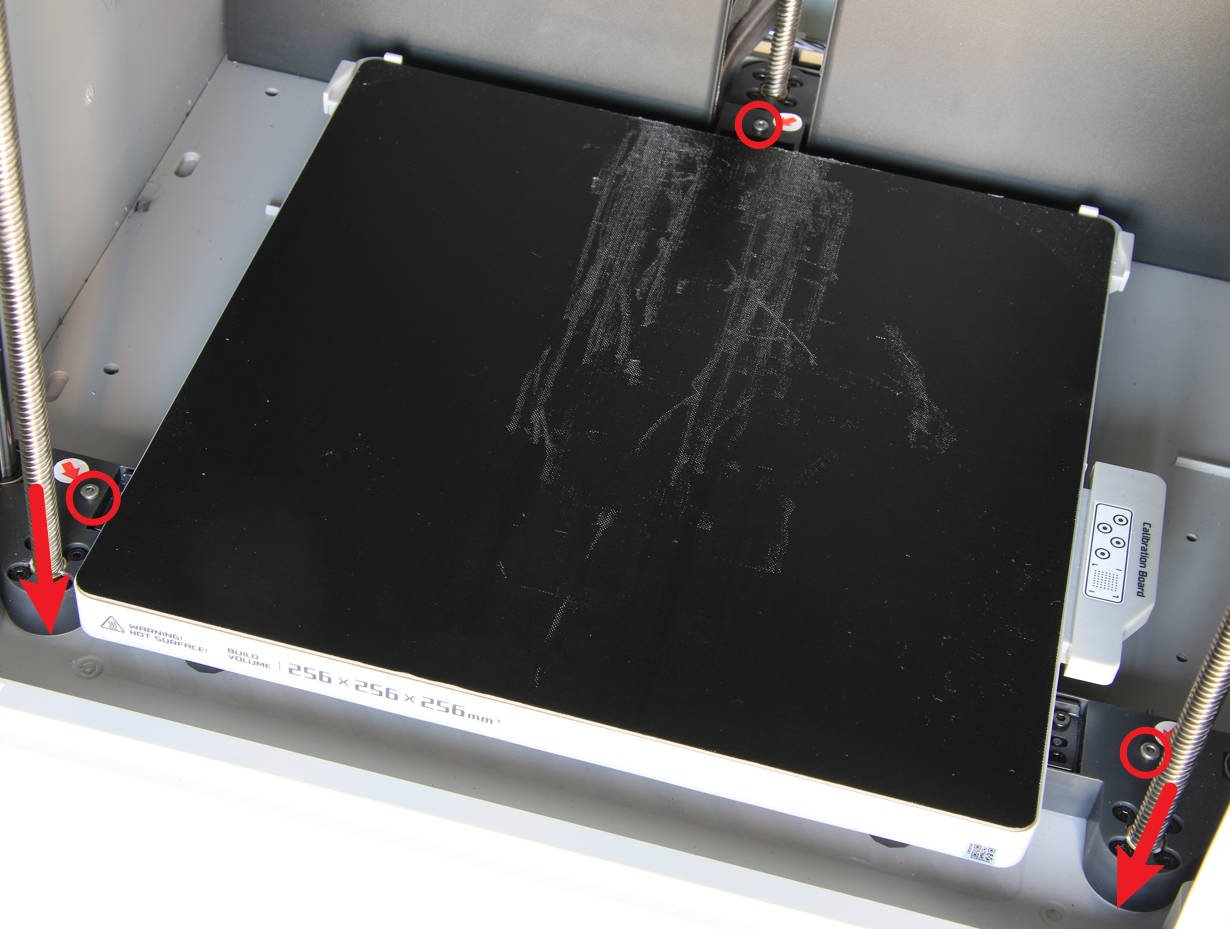

Put the printer on its side, pull the Z-axis belt, lower the heat bed to the bottom, and then lock the three sliders with three slider-fixing screws. Because the positions of the three sliders are already different, there may be cases where the block does not fit perfectly to the base.

¶ Step 4 - Untension the Z Belt

Release the Z tensioning spring, loosen the tensioner screw, and set the Z-axis belt to a loose state.

¶ Step 5 - Adjust the Z sliders

Press one end of the belt with your hand, turn the timing pulleys one by one, confirming that the Z slider at the corresponding position is adjusted to fit the base, and lock the slider fixing screws.

¶ Step 6 - Retensioning the Spring, and Unlock the Z Slider

|

Put the spring back into place to make it tense again.  |

Put the printer upright; then remove the 3 screws that lock the Z-axis slider  |

¶ Step 7 - Tensioning the Z belt, tighten the tensioner screw

|

Put the printer upside down, and pull the belt back and forth 3~5 times by hand.  |

Retighten the tensioner screw.  |

¶ Step 7 - Put the printer upright and install the screen

Put the printer upright, connect the screen, and reinstall the upper glass plate.

¶ Verify the functionality

Check the Z timing pulleys one by one by hand to confirm that there is no obvious looseness.

¶ Calibration steps after operation

- Connect the power, start up the printer

- Go to the setup menu on the screen as shown below to run bed leveling.

If there is an abnormality, please check whether there is a problem with the assembly, and run the device calibration again after troubleshooting. If the problem persists, please contact the Bambu Lab service team for further assistance.

¶ End Notes

We hope that the detailed guide we shared with you was helpful and informative.

We want to ensure that you can perform it safely and effectively. If you have any concerns or questions regarding the process described in this article, we encourage you to reach out to our friendly customer service team before starting the operation. Our team is always ready to help you and answer any questions you may have.

Click here to open a new ticket in our Support Page.

We will do our best to respond promptly and provide you with the assistance you need.