¶ Observation

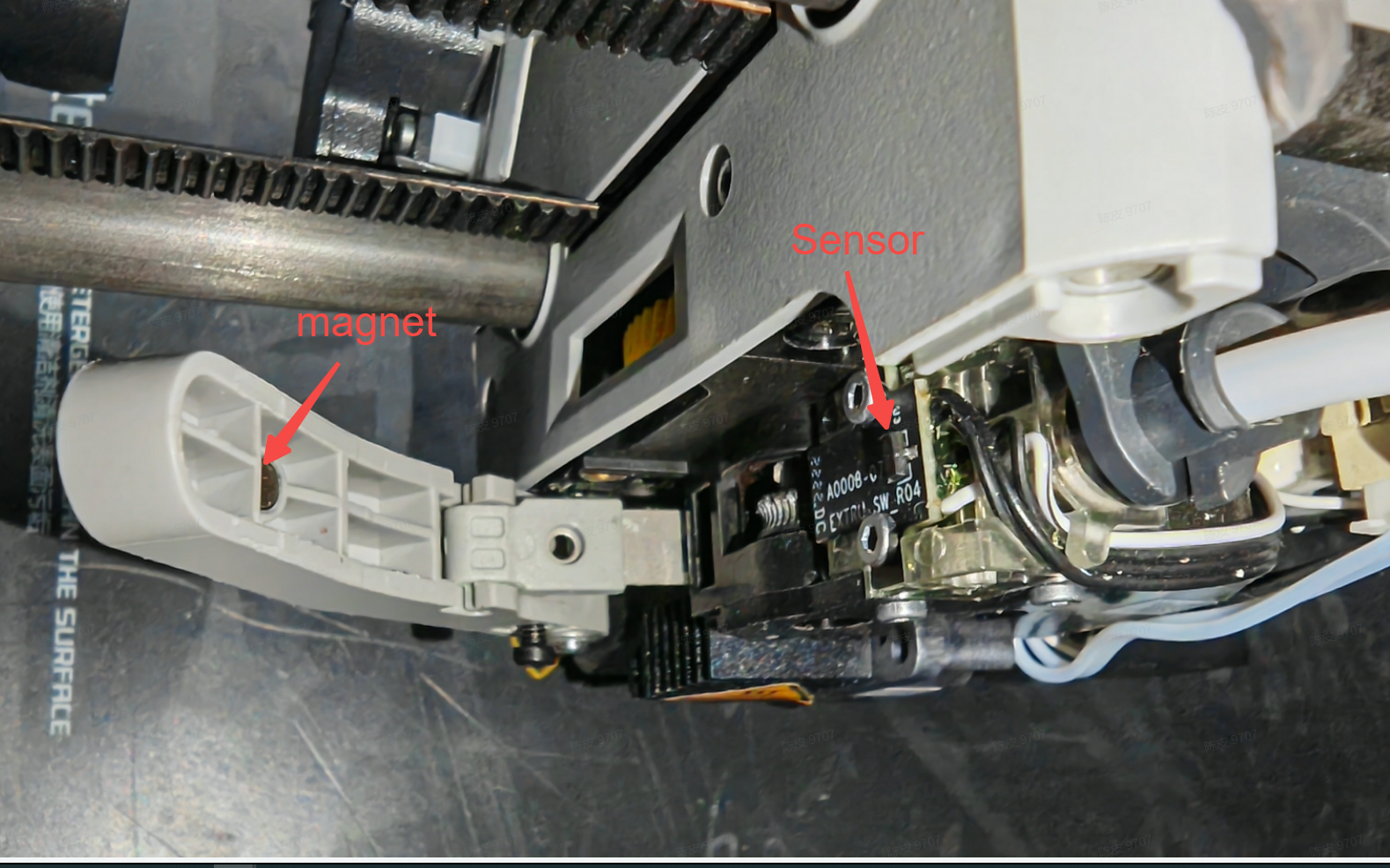

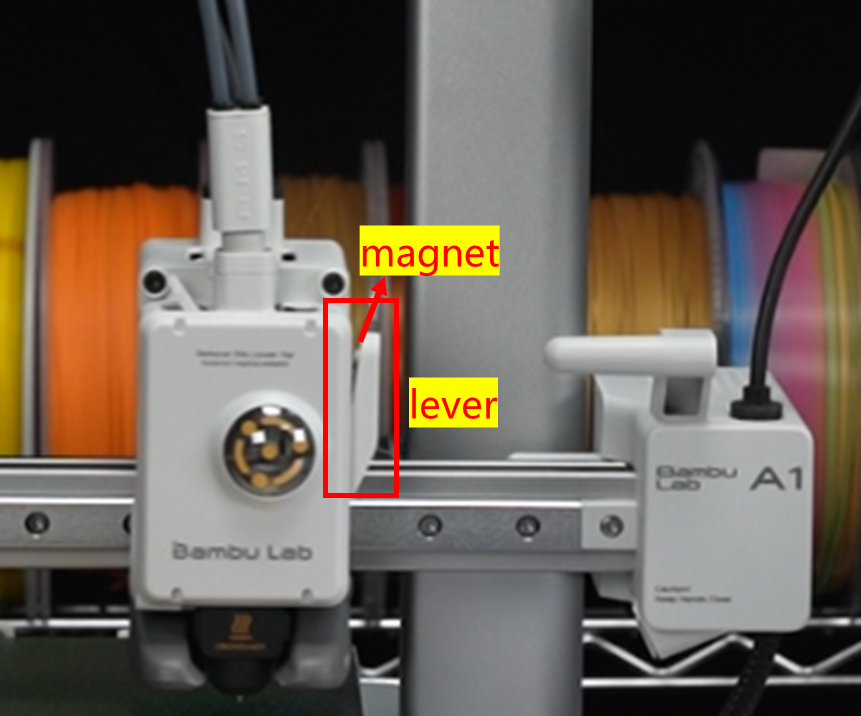

When the printer either unloads or switches filaments, the cutter trims the filament prior to retracting it. During this process, the toolhead shifts, causing the upper lever block to press against the cutter lever. This action propels the blade to sever the filament within the extruder. Once the filament has been cut, the cutter lever will automatically spring back into place. The cutter lever is depicted in the image below.

X1/P1 series:

A1/A1mini

This error typically arises due to:

- Incorrect installation of the magnet/sensor;

- Inadequate contact between the sensor's cable and connector;

- Misplacement of the toolhead often results from the XY motor missing a step before the filament is cut.

¶ Troubleshooting

¶ Step1 Check the magnet/sensor

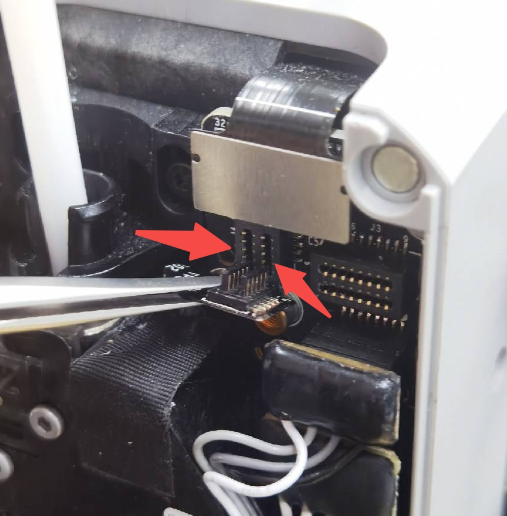

¶ X1 TH V8

Please also check the 10-pin terminal and reinsert the connector as needed. (Sometimes, it may require several attempts at reinsertion, and it's essential to remove any silicone residue on top using tweezers beforehand. If the error continues, please reach out to our customer support team.)

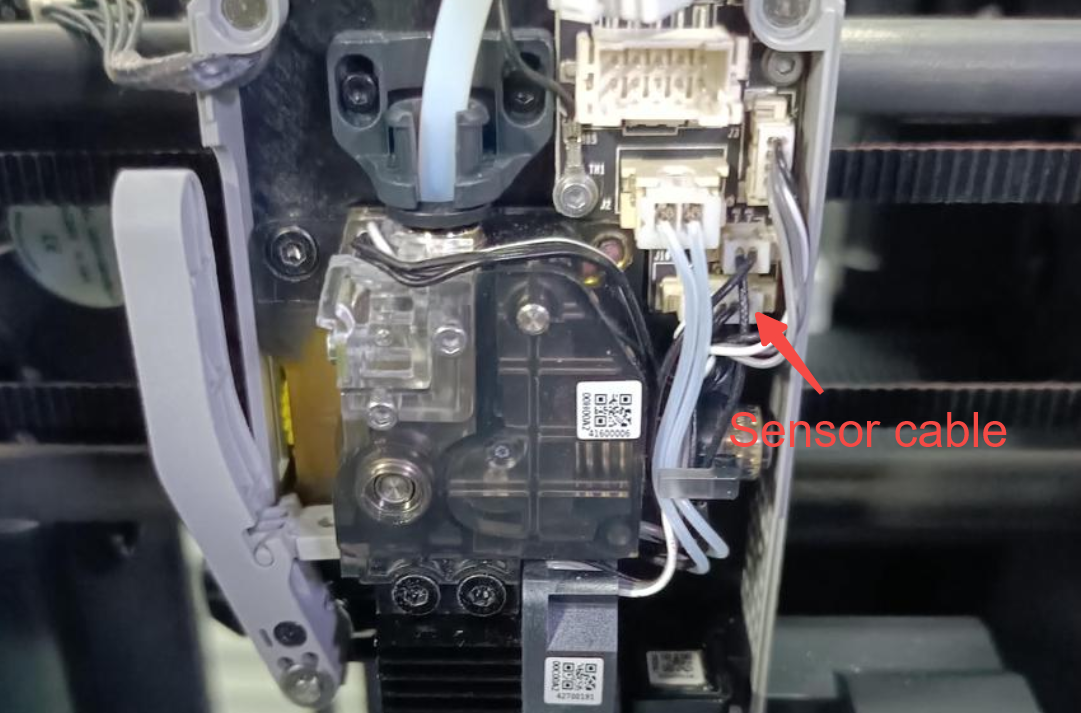

¶ X1 TH V9/P1

Please verify that the magnet/sensor is correctly installed and that the sensor's cable is properly connected. After confirming these, click "Retry".

¶ A1/A1mini

The feed, winding, and cutter hall sensors are integrated on a single circuit board. Please refer to this wiki to check. Cutter Hall Sensor Disassembly and Assembly

¶ Step2 Check the lost step of the XY motor

You can activate the video recording function to observe if the toolhead encounters any foreign objects during printing, which may cause it to lose its step: Enable the video recording function and export videos | Bambu Lab Wiki.

If the printed model does not exhibit layer misalignment due to lost steps, you can temporarily restart the printer to activate the "resuming prints after power outage" function. This will recalibrate the printer and allow the printing process to continue.

¶ Error message

HMS_0700-4500-0002-0002: The filament cutter's cutting distance is too large.The XY motor may lose steps.

0700-4500-0002-0002

¶ End Notes

We hope that the detailed guide we shared with you was helpful and informative.

We want to ensure that you can perform it safely and effectively. If you have any concerns or questions regarding the process described in this article, we encourage you to reach out to our friendly customer service team before starting the operation. Our team is always ready to help you and answer any questions you may have.

Click here to open a new ticket in our Support Page.

We will do our best to respond promptly and provide you with the assistance you need.