¶ What it is

As the hotbed homing is done by "sensing the force that nozzle touches the hotbed", there is a necessary precondition to make homing precise enough: the nozzle tip is clean, and the build plate surface is rigid. If this error message occurs, that means this precondition is detected not satisfied, which may be caused by :

- the build plate surface has bulge ;

- the nozzle tip isn't clean and there is remnant filament stuck on the nozzle tip

- software bug, the " soft detection " algorithm is not accurate enough...

¶ Safety warning and Machine state before starting operation

Be sure to note that some operations involve safety issues. For example, the whole machine should be powered off before replacing the circuit board. Necessary safety tips can reduce the probability of equipment damage. Usually, we recommend stating the state of the machine at the time of operation

¶ Troubleshooting guide

¶ Step 1 Check if there are bulges on the surface of the build plate or heat bed

Lighting from the front, keep your eyes close to the surface of the build plate and observe whether there are bulges on the surface of the build plate:

Here are examples of the bulge on the build plate and the heat bed:

|

|

The best way is to replace a new build plate surface, but if it is urgent, use a blade to make a few kerfs on the bulge surface to make it flat:

¶ Step 2 Clean the nozzle tip

Normally, the printer will clean the nozzle automatically when print starts, but there is still a chance that the nozzle is not clean enough ):

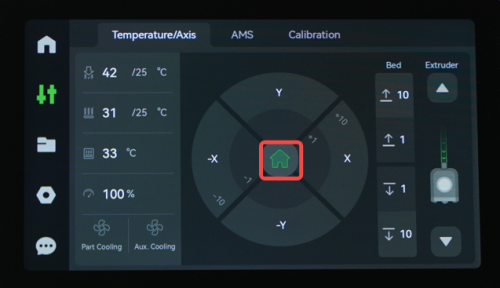

¶ Step 3: After completing all the steps above, click “home” again.

After the above steps, retry, tap the "home" button, and watch the homing process to check if the nozzle can touch the hotbed surface normally. If the homing is successful, then the homing z-axis failed error will disappear automatically.

¶ Error message

HMS_0300-0D00-0002-0001: Heatbed homing abnormal: there may be a bulge on the heatbed or the nozzle tip may not be clean.

“Heatbed homing abnormal: there may be a bulge on the heatbed or the nozzle tip may not be clean.”

0300-0D00-0002-0001

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

To ensure a safe and effective execution, if you have any concerns or questions about the process described in this article, we recommend submitting a Technical ticket regarding your issue. Please include a picture or video illustrating the problem, as well as any additional information related to your inquiry.