¶ What it is

¶ X/P Series Printer

Before sensing the force that is applied on the heat bed, the printer will test the sensitivity of each force sensor by vibrating the hotbed up and down.

If anything touches the heat bed, the printer will get the wrong sensitivity parameters and make subsequent procedure works abnormally.

Below are the possible reasons that the printer thinks there were external disturbances occurred:

- The build plate hasn't been placed correctly.

- The printer is placed on an unstable platform, such as a cushion or a shaky table.

- There is an object obstructing the Z-axis motor or the Z-axis synchronous belt wheel on the workbench.

- When the print bed approaches the bottom of the chamber, the Z-axis slider gets stuck due to an object at the bottom.

- There are foreign objects on the Z-axis slider, or the Z-axis linear bearings are protruding.

- The print bed is interfered with by the waste chute or the print board is interfered with by the printer liner.

- The print bed cable is tightened too much, causing interference with the movement of the print bed.

- Incorrect specification screws were used during the installation of the AMS-HUB.

- The Z-axis slider assembly has abnormal tolerances.

- The force sensor or its signal chain is malfunctioning, resulting in the processor not receiving data from the force sensor.

Please note that the above list only includes some possible causes, and there may be other factors contributing to this error in actual situations.

¶ X/P Series Printer Troubleshooting guide

¶ Step 1: Check whether build plate is placed correctly

Please refer to: HMS_0300-0D00-0001-0003: The build plate may not be properly placed. If this message appears repeatedly, please check the Wiki for more reasons.

¶ Step 2: Check for objects at the bottom of the machine

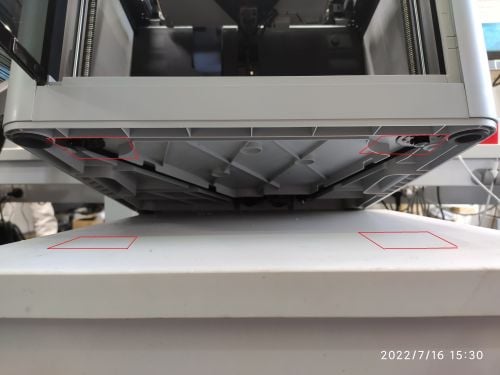

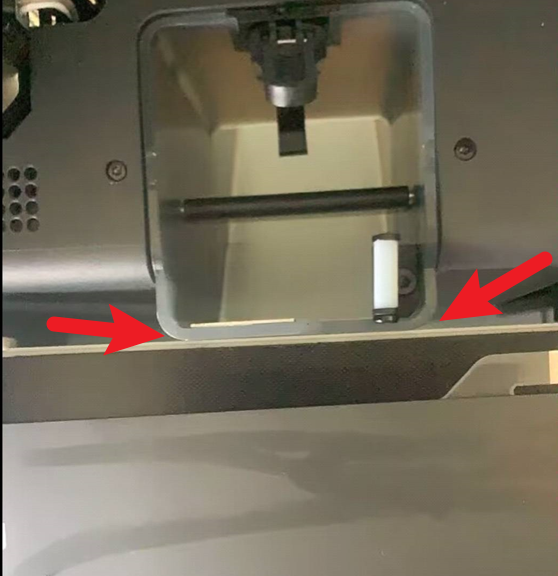

Lift the printer front a bit, and check if there is anything that will stick to the Z-axis timing belt. Notice that the rubber foot is stuck on to the bottom of the printer, if the printer is pushed on the place surface, the rubber foot may get pushed off and gets stuck into the Z-axis timing belt ( where as shown in the red box below ):

¶ Step 3: Check whether Z motor and belt is stuck

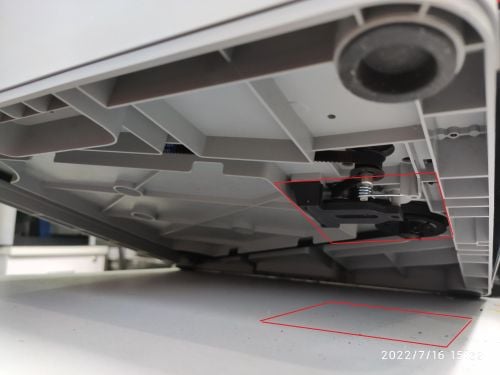

Lift the back of the printer a bit, and check if there is anything that will stick the Z-motor and timing belt wheel (as shown in the red box below ):

¶ Step 4: Check whether Z slider is stuck by for foreign object

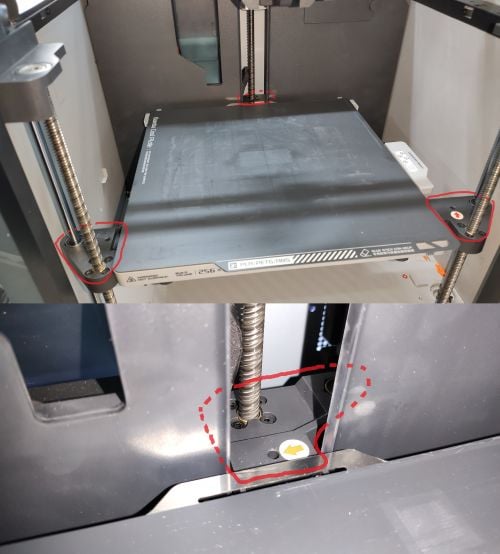

Lower the heat bed, and check if there is anything on the Z-axis slider upper surface, especially the rear one that is partly hidden behind the inner liner :

In addition to checking the surface of the slider for foreign objects, you will also need to check whether the Z-axis bearing is raised in this step.

If you find the bearing is raised, please refer to the operation video below to reset the bearing. It is important to note that before following the video, please remove the hotend assembly of the toolhead (click here for a guide to disassembling the hotend assembly) and then perform the operation in the video.

If you encounter any difficulties during this process, please contact after-sales service for assistance.

|

|

The purpose of this operation is to press the raised bearing back into place using the retaining block:

https://public-cdn.bblmw.com/wiki/X1/fix_bearing_up.mp4

Raised bearings are usually caused by the presence of foreign material, such as scrap, in the three holes at the bottom of the linear rods, which causes the bearing to be squeezed and raised out of place. If there is any foreign material in these holes, make sure they are thoroughly cleaned out or the failure may recur.

¶ Step 5: Check whether the excess chute is interfering

Check if there is visible interference between the heatbed and the excess chute.

|

|

If you find that the excess chute is interfering, click to view this wiki page for a solution.

¶ Step 6: Check whether the cable is too tight

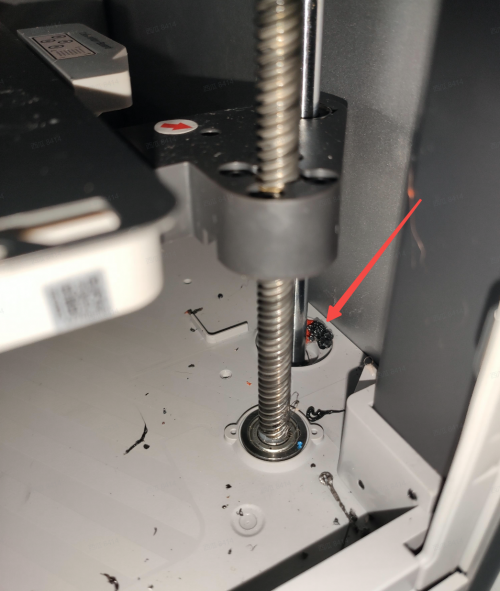

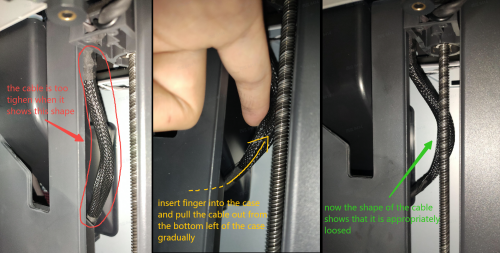

raise the hotbed slowly, until it almost reaches the nozzle, then look into the inside of the liner from the chamber, to see if the hotbed cable next to the z-axis lead screw is dragged tight. If the shape of the cable is similar the the picture below, then it may be dragged tight:

Then you have to insert your finger into the gaps and drag the cable out from the inner of the electric case, as shown below, CAUTION: the liner edge may be a bit sharp, be careful or wear gloves when doing this step

If the hotbed cable is stretched, click on this wiki page for the solution.

¶ Step 7: Check AMS hub/ Filament buffer's screws

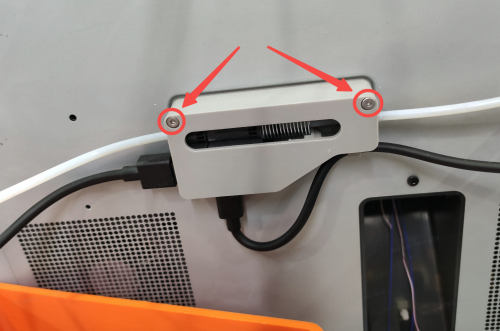

If you have installed the AMS-HUB or AMS-BUFFER, if the screw is over tightened, that may also stick the z-axis when the bed is near the nozzle, so try loose these two screws for 1~2 rounds :

¶ Step 8: Re-adjust Z sliders

the steel rod may have moved under violent shipping, so the z-axis slider needs to be re-adjusted, see the picture below:

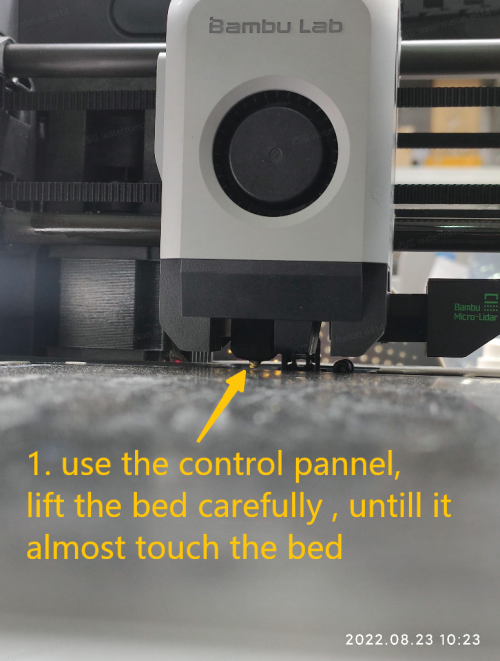

¶ 8.1: Use the control panel, and lift the bed carefully until it almost touches the bed

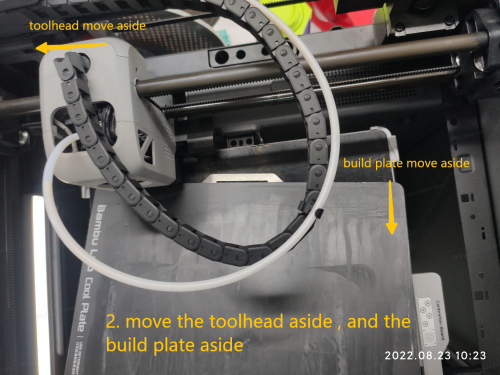

¶ 8.2: Move the toolhead aside and the build plate aside

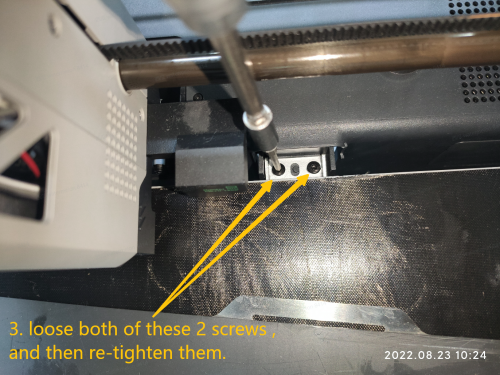

¶ 8.3: Loosen both of these 2 screws and re-tighten them (at the back)

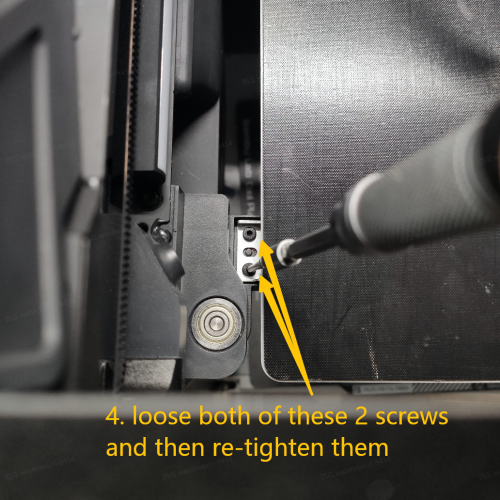

¶ 8.4: Loosen both of these 2 screws and re-tighten them (on the left)

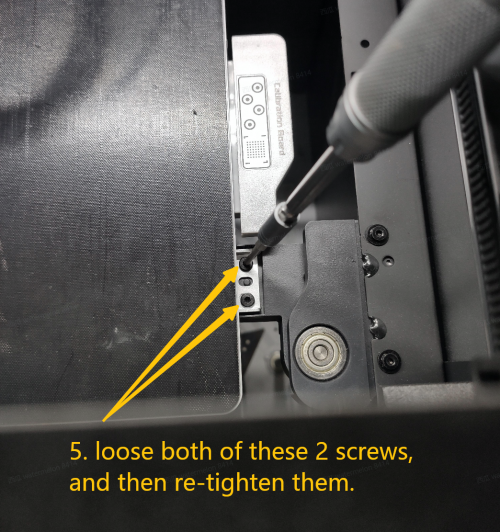

¶ 8.5 Loosen both of these 2 screws and re-tighten them (on the right)

¶ Step 9: After completing all the steps above, click “home” again.

After the above steps, retry, tap the "home" button, and watch the homing process to check if the nozzle can touch the hotbed surface normally. If the homing is successful, then the homing z-axis failed error will disappear automatically.

If it still shows this error, please contact the customer support team.

¶ A1 Printer

- Please ensure that the heat bed is not stuck or rubbed during vibration;

- Ensure that the printer is placed on a stable surface without abnormal shaking;

- Remove the build plate and remove the silicone protective cover of the screw holes, expose the screw holes, and remove the screws;

|

|

4. Turn the heat bed over and expose the bottom structure of the heat bed to see the heat bed acceleration sensor, and check whether the device is significantly loose or damaged.

|

|

5. If the sensor is not loose, it may be damaged, please refer to this wiki to replace the sensor: A1 Heatbed Unit Installation Tutorial | Bambu Lab Wiki

¶ Error message

HMS_0300-0A00-0001-0004: An external disturbance was detected on force sensor 1. The heatbed plate may have touched something outside the heatbed.

“An external disturbance was detected on force sensor 1. The heatbed plate may have touched something outside the heatbed.”

The error code below shows the same issue with different force sensors:

0300-0A00-0001-0004

0300-0B00-0001-0004

0300-0C00-0001-0004

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

If this guide does not solve your problem, please submit a technical ticket, we will answer your questions and provide assistance.

If you have any suggestions or feedback on this Wiki, please leave a message in the comment area. Thank you for your support and attention!