¶ 1. Introduction

X1E offers an additional chamber temperature heating control feature, with a max chamber temperature of 60 ℃. Higher chamber temperatures can suppress the warping of certain high-temperature filaments' prints and provide higher interlayer strength (layer adhesion) of some prints. When printing high-temperature filaments such as PC, PA-CF, PAHT-CF, PET-CF, PPA-CF, PPS and PPS-CF, selecting X1E and enabling a chamber temperature of 60 °C can result in improved dimensional accuracy and visual quality of some prints. Furthermore, when printing the aforementioned high-temperature filaments, selecting X1E and enabling a chamber temperature of 60 ℃ can enhance the strength, especially the interlayer strength, of some prints.

Warning: It is strongly recommended not to enable high chamber temperature when printing PLA, PETG, TPU, PVA and other low-temperature filaments. Enabling high chamber temperature may cause these filaments to soften and become lodged in the extruder, resulting in clogging issues. When printing such low-temperature filaments, it is advised to set the chamber temperature to 0 °C (i.e., disable chamber temperature control).

¶ 2. Recommended chamber temperatures for various filaments

(1) PLA, PETG, TPU, PVA, PLA's supports and other low-temperature filaments:

Chamber temperature setting: The default chamber temperature setting is off (0 °C).

Tips: To prevent cloggings, avoiding high chamber temperatures and set the chamber temperature to 0 °C when printing low-temperature filaments is highly recommended. . Additionally, when the bed temperature is equal to or greater than the filament's softening temperature, it is advised to open the front door and remove the top cover of the printer. For example, the softening temperatures of most kinds of PLA and PETG are about 45 °C and 70 °C respectively.

(2) ASA, ABS:

Chamber temperature setting: The default chamber temperature setting is off (0 °C).

Tips: When the chamber temperature is enabled, some models with lager size and/or higher infill density can experience reduced warping, resulting in improved print quality and dimensional accuracy. Additionally, the interlayer strength of some models can be enhanced. However, the preparation time before printing will get longer, and the air filtration will get worse. In order to obtain better air filtration effect, we choose to disable the chamber temperature by default. Please decide whether to turn on the chamber temperature based on the actual situation. Our suggestion is that for those prints that are prone to warping, that is, those with larger sizes and/or higher infill density, or those with higher strength requirements, please enable the chamber temperature to be 60°C, while for other normal prints, it is recommended not to enable it.

(3) PC, PA, PA-CF, PAHT-CF, PA6-CF, PET-CF, PPA-CF, PPA-GF, PPS, PPS-CF and other high-temperature filaments:

Chamber temperature setting: The default chamber temperature setting is on (60 °C).

Tips: With high chamber temperatures, some models with lager size and/or higher infill density can experience reduced warping, improving quality and dimensional accuracy. Additionally, the interlayer strength of some models can be enhanced.

¶ 3. Chamber Temperature Setting Instructions

¶ 3.1 Setting Chamber Temperature (Recommended) in Bambu Studio

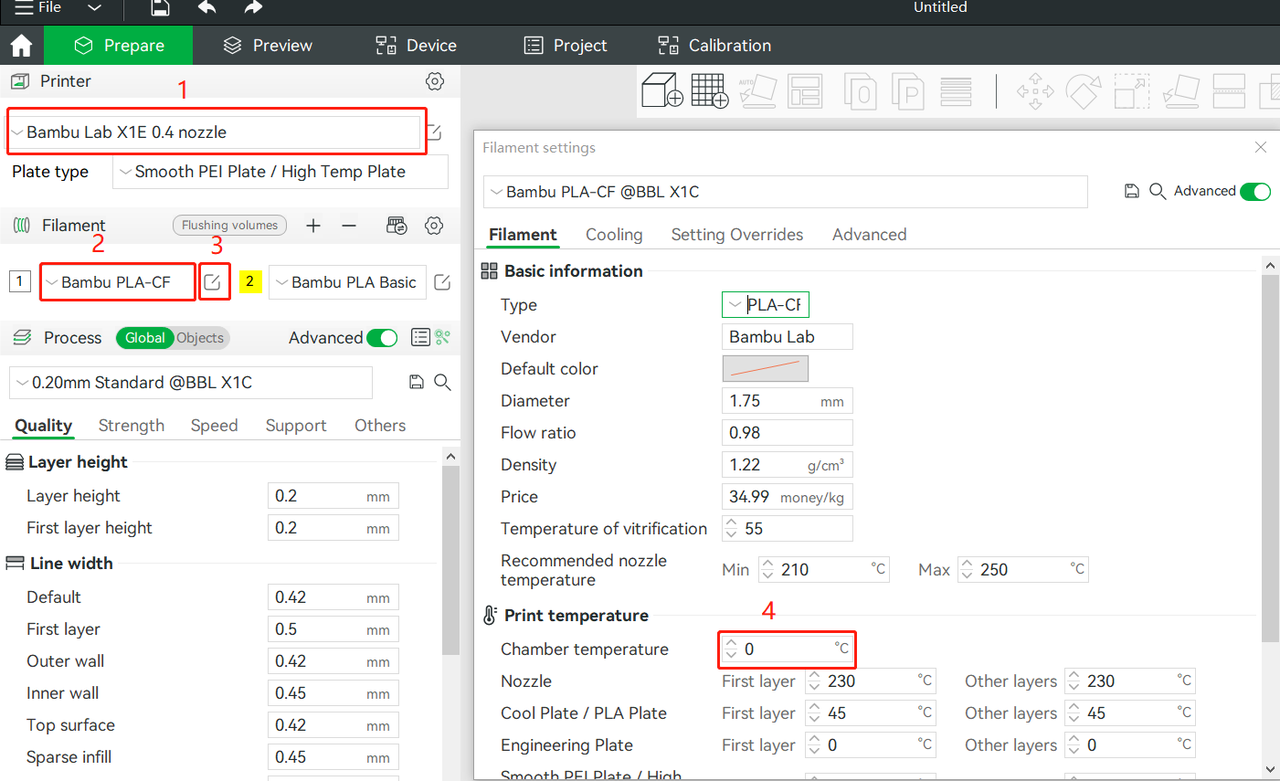

¶ Step 1: Select the X1E model.

¶ Step 2: Select the desired filament type.

¶ Step 3: Click on the filament parameter editing button.

¶ Step 4: Locate the chamber temperature setting field.

The chamber temperature can be set within the range of 0 °C to 60 °C (the chamber temperature heating control module only operates within the range of 40 °C to 60 °C).

Setting the chamber temperature to 0 °C represents disabling the chamber temperature heating control.

When the chamber temperature is set below 40 °C, the chamber temperature heating control will not take effect. In other words, setting the chamber temperature between 0 °C and 40 °C (including 0°C but not including 40 °C) will result in the same practical effect.

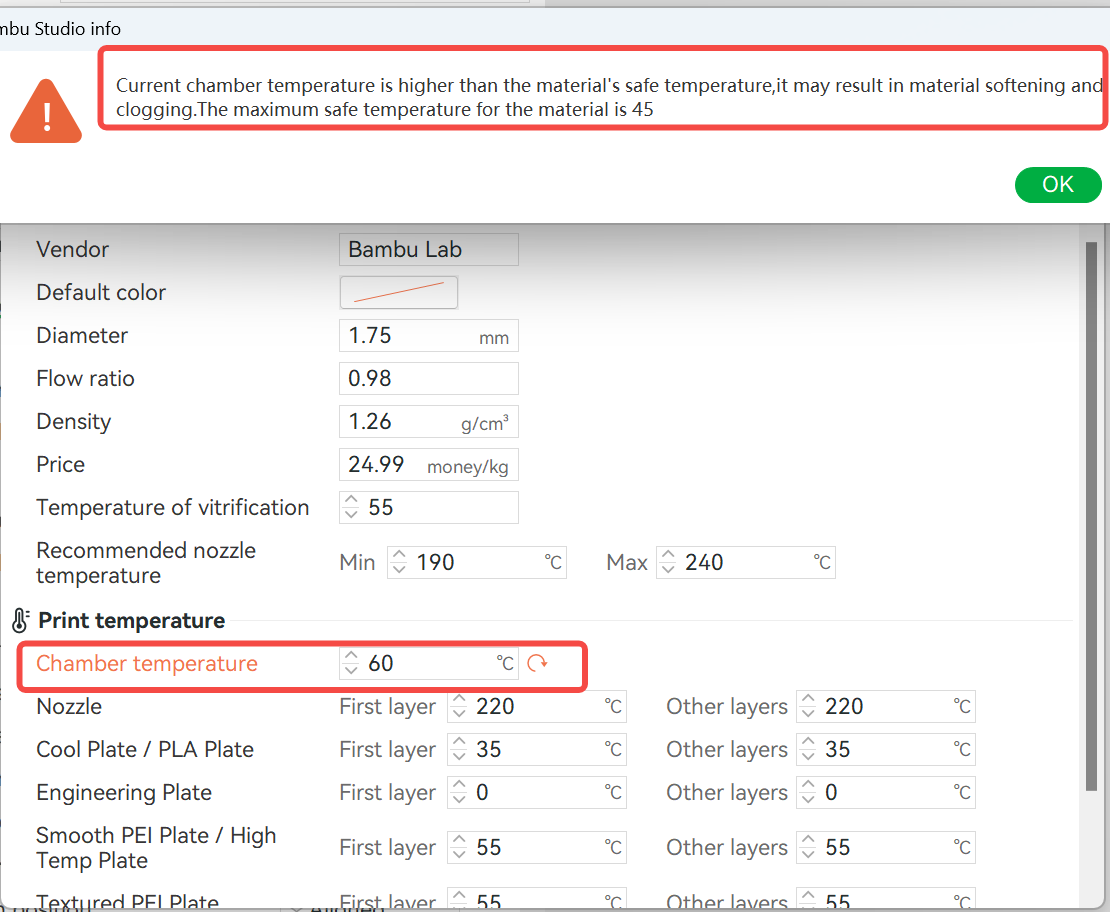

For a low-temperature filaments, to prevent clogging, it is recommended to set the chamber temperature below the designated safe temperature. If the chamber temperature is set above the safe temperature, a pop-up prompt will appear to alert the user.

In the case of multi-color printing, the actual chamber temperature will be the highest chamber temperature set among the multiple filaments being used. Thus, to avoid cloggings of any filaments that are actually being used, make sure that the highest chamber temperature is safe enough for all of them before starting.

Note: With firmware updates, the user interface (UI) may undergo slight changes.

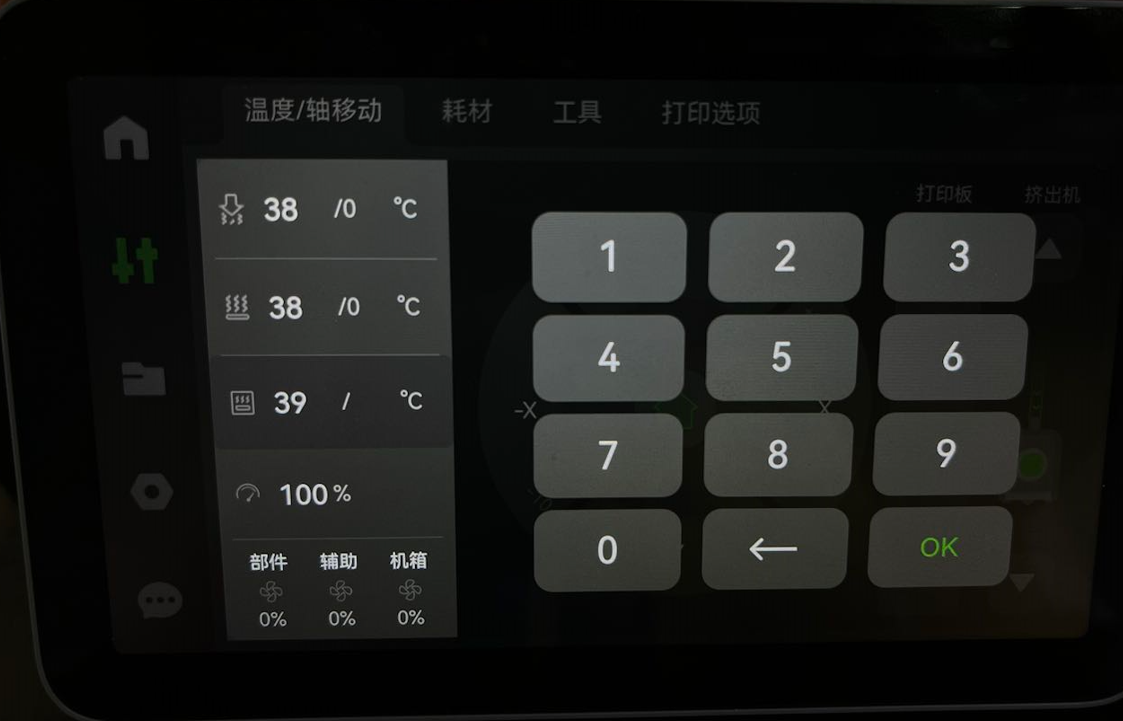

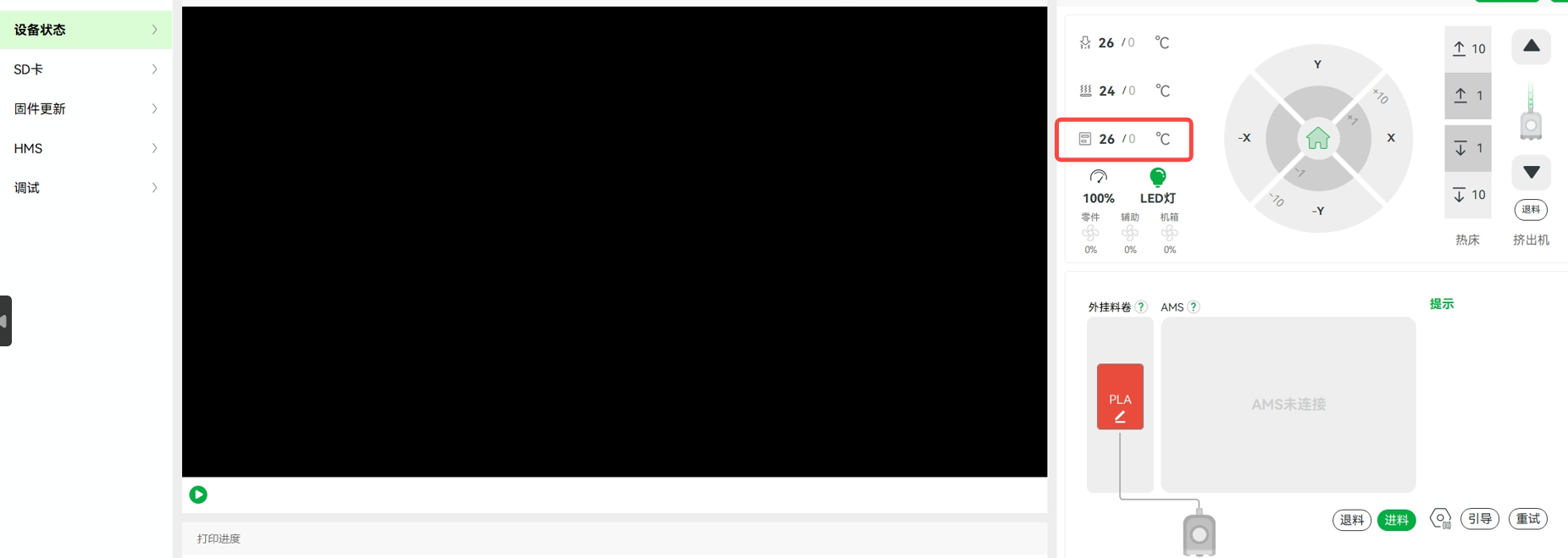

¶ 3.2 Setting Chamber Temperature on the "Device Control" Page in Bambu Studio, Bambu Handy and Printer UI

|

|

|

The logic for setting the temperature is the same across all three approaches mentioned. Taking the example of setting the temperature through the printer's screen UI, here is an explanation of how to actively set the chamber temperature. Here are some important points to note regarding chamber temperature settings:

(1) The target temperature for enabling chamber temperature cheating control can only be set between 40°C and 60°C (including 40 °C and 60 °C). In particular, if there are low-temperature filament (such as PLA, PETG, TPU) present in the hot end, the target temperature for chamber temperature heating control will be limited to the range of 40 °C to 45 °C (including 40 °C but not including 45 °C) to prevent clogging.

(2)When setting the chamber temperature below 40 degrees Celsius (including 0 °C and other values below 40 °C), it represents disabling the chamber temperature heating control. In such cases, the system will automatically set the chamber temperature target to 0 °C.

(3)When setting the chamber temperature above 60 degrees Celsius, the setting will not take effect, and the system will maintain the previous chamber temperature state.

(4)If the current chamber temperature or target chamber temperature exceeds 45 degrees Celsius, it is not allowed to load low-temperature filament (such as PLA, PETG, TPU) to prevent clogging.

¶ Extended reading: The Air Filtration Module of X1E

¶ 4.1 The Purpose of the Air Filtration Module

Absorbing VOC or particles released during the printing process of filament like ABS, ASA, PETG.

¶ 4.2 The impact of high chamber temperature on the air filtration module

When the chamber temperature is high, the filter temperature increases, and the adsorption capacity of the activated carbon for VOC and particles may decrease.

When the chamber temperature is high, the overall temperature of the machine increases, causing the cooling fan of the back panel power supply to run at full speed. If the airflow fan speed of the air filtration module is set lower than the default setting during this time, it may result in the inability to maintain negative pressure inside the chamber. As a result, some gases may escape through gaps in the chamber instead of being expelled through the filter.

¶ 4.3 Estimated lifespan (based on 8 hours of daily printing)

When printing with low VOC and particulate emission filaments such as PLA, PC, and their carbon fiber (CF), glass fiber (GF) composites, the filter cartridge can be used for approximately 3 months.

When printing with high VOC or particle emission filaments such as ABS, PETG, PA, and their carbon fiber (CF), glass fiber (GF) composites, the active carbon filter may need to be replaced approximately every month. These filaments tend to release a higher amount of VOCs and particulate matter during the printing process, which can result in faster saturation of the filter. Regular replacement of the active carbon filter is important to maintain effective filtration and ensure a cleaner printing environment.