¶ X1E Chamber Heater Unit

In order to provide a higher and more stable temperature for the printer chamber, we have added a heater unit and other supporting components to the X1E printer.

This page provides the relevant guidelines for disassembling and assembling the X1E chamber heater unit and explains the relevant precautions. You can also refer to this page for disassembling and assembling the replaceable parts involved in this process.

¶ Parts List

Associated Parts List

| NO. | Descriptions | Pics | NO. | Descriptions | Pics |

| 1 | Filter cover |

|

2 | Activated Carbon Air Filter |

|

| 3 | X1E Rear Metal Panel |

|

4 | Excess chute |

|

| 5 | Chamber Temperature Regulator fan |

|

6 | Chamber Heater Control Board |

|

| 7 | X1E Right metal panel |

|

8 | Chamber Heater Unit |

|

¶ Screws list

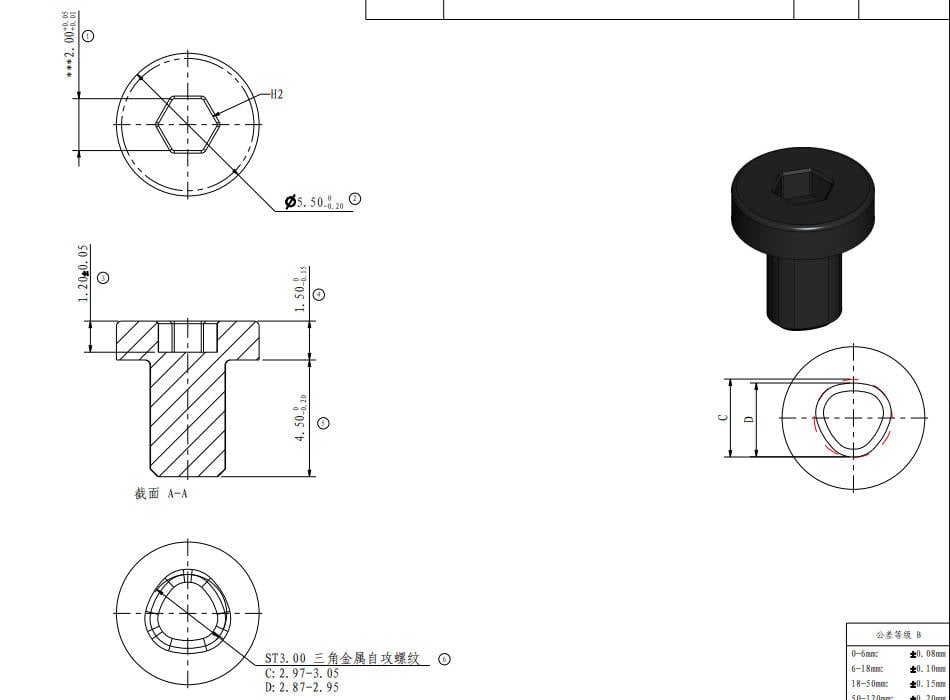

| Model | Position | Drawing | Model | Position | Drawing | ||

| Screw A | ST3*4.5 |

Rear panel, Right panel (9PCS) |

|

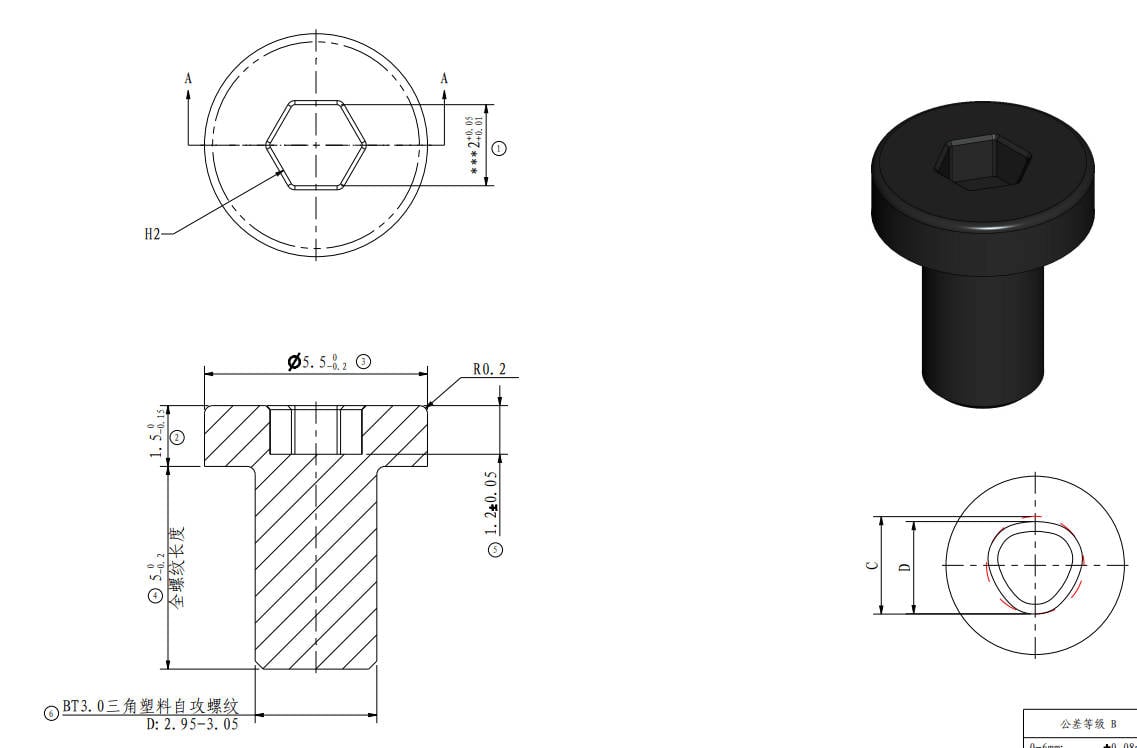

Screw B |

BT3*5

|

Rear panel, Air duct (4PCS/3PCS) |

|

| Screw C | M3*4.5 |

Rear panel, Right panel (1PCS、15PCS) |

|

Screw D | BT2*8 |

Excess chute, Power protective cover (2PCS/ 7PCS) |

|

| Screw E | BT2*5 |

Excess chute (1PCS) |

/

|

Screw F | BT3*8 | Chamber Temperature Regulator fan, Heater Unit(1PCS/2PCS) |

|

| Screw G | BT3*6 |

Chamber Heater Control Board (4PCS) |

|

Screw H | MG3*12 |

Chamber Heater Unit (1PCS) |

|

¶ Tools and materials needed

H1.5 /H2.0 hex key

Cross screwdriver

Needle nose pliers

¶ Safety Warning

IMPORTANT!

It's crucial to power off the printer before performing any maintenance work on the printer and its electronics, including tool head wires, because leaving the printer on while conducting such tasks can cause a short circuit, which can lead to additional electronic damage and safety hazards.

When you perform maintenane or troubleshooting on the printer, you may be required to disassemble some parts, including the hotend. This process can expose wires and electrical components that could potentially short circuit if they come into contact with each other or with other metal or electronic components while the printer is still on. This can damage the electronics of the printer and cause further damage.

Therefore, it's essential to switch off the printer and disconnect it from the power source before doing any maintenance work. This will prevent any short circuits or damage to the printer's electronics. By doing so, you can avoid potential damage to the printer's electronic components and ensure that the maintenance work is performed safely and effectively.

If you have any concerns or questions about following this guide, open a new ticket in our Support Page and we will do our best to respond promptly and provide you with the assistance you need.

¶ Disassembly

¶ Step 1: Remove the Activated Carbon Air Filter

Remove the glass cover plate, lower the heatbed to the bottom by pulling the Z-axis belt, and expose the entire filter cover, as shown in Figure 1-1-1, then uncover and remove the filter cover;

As shown in Figure 1-1-2, pull the strap of the filter with two hands to remove the Activated Carbon Air Filter.

|

|

¶ Step 2: Remove the Rear Panel

Remove the glass cover plate, and then as shown in Figure 1-2-1, remove 9 screws A, 4 screws B, and 1 screw C with the H2.0 hex key;

As shown in Figure 1-2-2, first push the rear panel to the right a little bit, and loosen the rear panel from the tensioner on the right side;

As shown in Figure 1-2-3, apply force to the left, release the rear panel from the left tensioner, and remove the rear panel.

|

|

|

¶ Step 3: Remove the Excess Chute

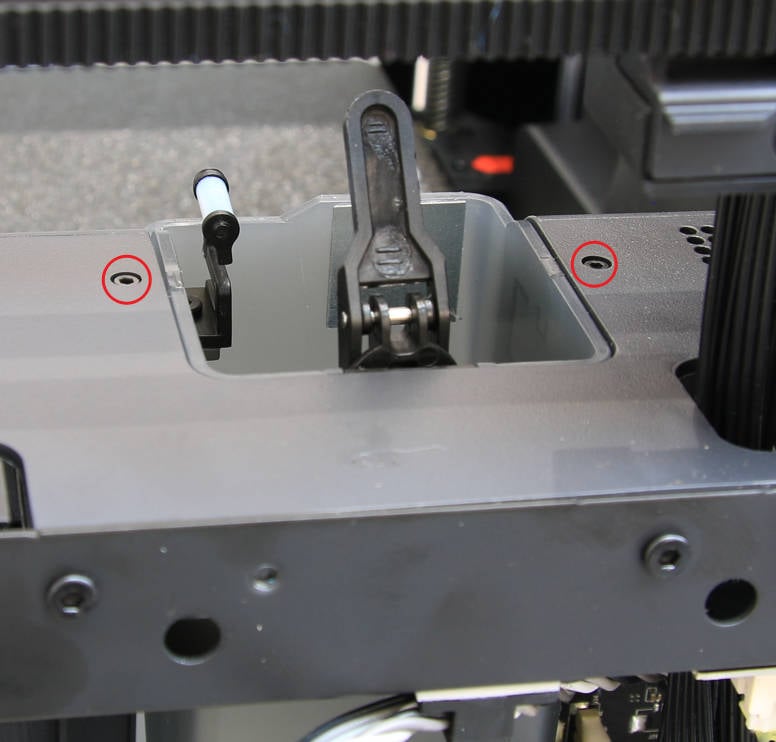

As shown in Figure 1-3-1, remove the 2 screws D with the H1.5 hex key;

As shown in Figure 1-3-2, remove 1 screw E with the H2.0 hex key;

Remove the excess chute, as shown in Figure 1-3-3.

|

|

|

¶ Step 4: Remove the Chamber Temperature Regulator Fan

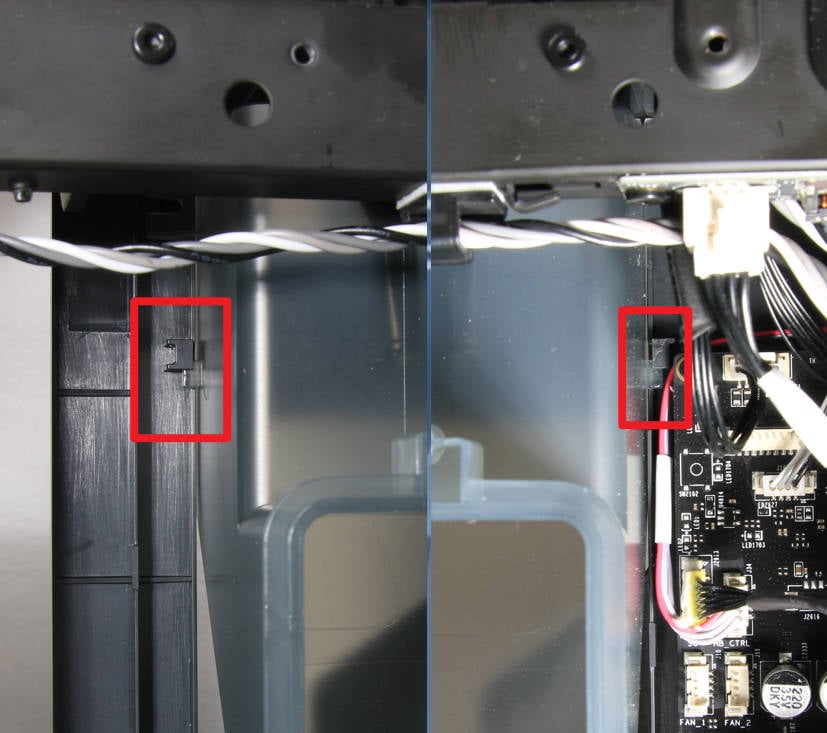

As shown in Figure 1-4-1, remove the 3 screws B with the H2.0 hex key and remove the air duct;

As shown in Figure 1-4-2, disconnect the fan connection from the interface labeled FAN1 on the main control board, loosen the fan cable from the three cable ties, and remove 1 screw F with the H2.0 hex key;

Remove the chamber temperature regulator fan, as shown in Figure 1-4-3.

|

|

|

¶ Step 5: Remove the Chamber Heater Control Board

As shown in Figure 1-5-1, disconnect the 8 connecting cables from the heater control board. Note that the connector plugs indicated by the arrows have a buckle. When unplugging, you need to press the buckle to unlock;

As shown in Figure 1-5-2, remove the 4 screws G with an H2.0 hex key and remove the heater unit control board;

As shown in Figure 1-5-3, the numbered connectors are connected to the following objects:

1- Chamber Heater Unit(Black, GND) 2- Chamber Heater Unit(Red,24V) 3- Internal Power Supply (24V) 4- Network Interface and AMS Connection Board 5- Internal Power Supply NTC 6- Power Cooling Fan 7- Chamber Heater Unit FAN 8- Chamber Heater Unit NTC

|

|

|

¶ Step 6: Remove the Right Metal Panel

As shown in Figure 1-6-1, remove the 4 screws C behind the right metal panel with an H2.0 hex key ;

As shown in Figure 1-6-2, tear off the EVA pad and remove 1 screw C on the top of the right metal panel with an H2.0 hex key;

As shown in Figure 1-6-3, remove the 4 screws C on the right front column with an H2.0 hex key;

As shown in Figure 1-6-4, place the printer on its side with the right side panel facing up, and remove the 2 screws C at the bottom with an H2.0 hex key;

As shown in Figure 1-6-5, apply force on both sides of the right metal panel at the same time to remove it from the printer;

As shown in Figure 1-6-6, in addition to the screws, the right metal panel is foam-bonded to the printer at the middle beam, so it is not that easy to remove the right metal panel. It is recommended that at least two people work together.

|

|

|

|

|

|

¶ Step 7: Remove the Chamber Heater Unit

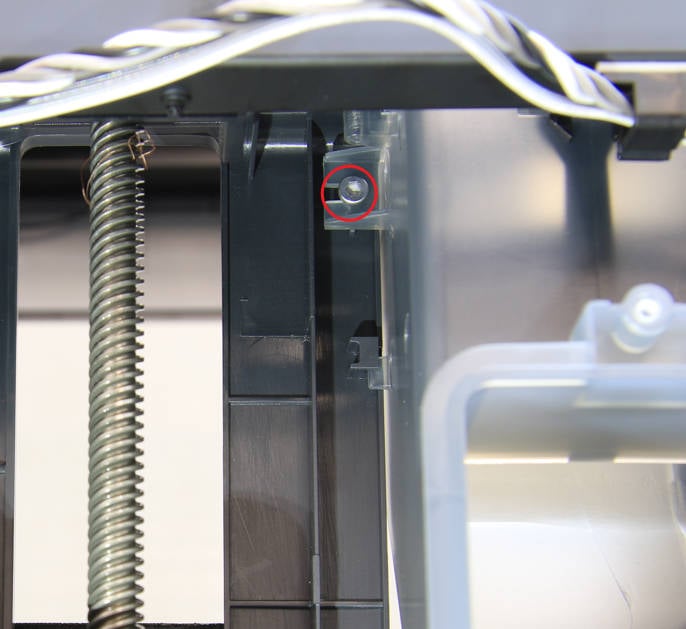

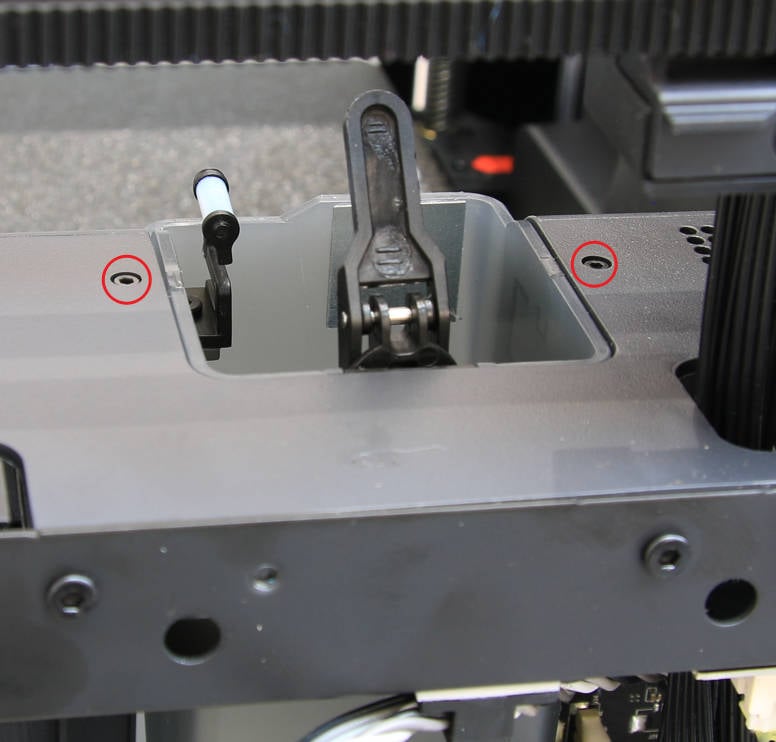

As shown in Figure 1-7-1, remove the 2 screws F at the bottom with an H2.0 hex key ;

As shown in Figure 1-7-2, place the printer upright, pull out the heater unit's cables from the hole on the right rear column, and apply force vertically upward to loosen the heater unit from the bottom base;

As shown in Figure 1-7-3 and Figure 1-7-4, use the upper fixing screw as a fulcrum to rotate the heater unit to remove it from the beam;

Note: There is a rubber block on the fixed position above the heater unit, so there is no need to worry about damage when rotating it to remove the heater unit, as shown in Figure 1-7-5;

As shown in Figure 1-7-6, use pliers and an H2.0 hex key to remove the screws H and nut left on the beam.

|

|

|

|

|

|

¶ Assembly

¶ Step 1: Install the Chamber Heater Unit

As shown in Figure 2-1-1, align the two protruding pillars with the installation slots and place the heater unit in place;

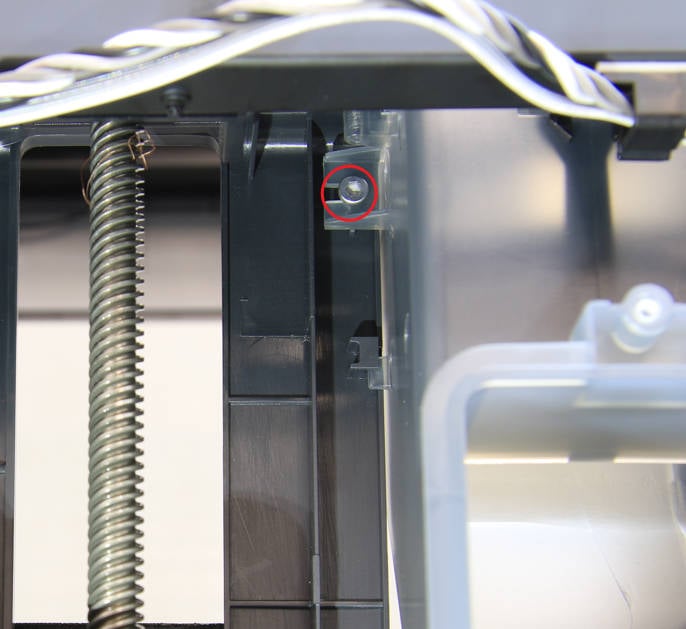

As shown in Figure 2-1-2, reinstall the removed screw H and nut into their original positions, press the nut with your hands or clamp the nut with needle-nose pliers, and then lock the screw H;

As shown in Figure 2-1-3, pass all the cables of the heater unit through the cable hole between the right rear column and the inner sheld;

As shown in Figure 2-1-4, place the printer on its left side and lock 2 screws F from the bottom of the base to fix the heater unit.

|

|

|

|

¶ Step 2: Install the Right Metal Panel

As shown in Figure 2-2-1, install the right metal panel to the printer and align the installation position;

As shown in Figure 2-2-2, lock 2 screws C on the base;

As shown in Figure 2-2-3, place the printer upright, align the screw holes, lock 1 screw C on the top beam, and stick the EVA pad back to its original position;

As shown in Figure 2-2-4, lock 4 screws C in the right front column;

As shown in Figure 2-2-5, lock 4 screws C at the rear part of the right metal panel.

Note: When locking the screws on the right metal panel, the position may be deviated, making it difficult to lock in the screws. For the 8 screws on the right front column and the rear, you can leave them unfastened until all the screws are screwed in.

|

|

|

|

|

¶ Step 3: Install the Chamber Heater Control Board

As shown in Figure 2-3-1, install the Chamber Heater Control Board to the printer and secure it with 4 screws G;

As shown in Figure 2-3-2, be sure to check the connector information before connecting the cable, the numbered connectors are connected to the following objects:

1- Chamber Heater Unit(Black, GND) 2- Chamber Heater Unit(Red,24V) 3- Internal Power Supply (24V) 4- Network Interface and AMS Connection Board 5- Internal Power Supply NTC 6- Power Cooling Fan 7- Chamber Heater Unit FAN 8- Chamber Heater Unit NTC

As shown in Figure 2-3-3, according to the above connector information, connect the 8 cables to the corresponding connectors.

|

|

|

¶ Step 4: Install the Chamber Temperature Regulator Fan

As shown in Figure 2-4-1, install the chamber temperature regulator fan, fix the fan with 1 screw F, then arrange the fan cable into the cable buckles along the route indicated by the arrow in the figure, and finally connect it to the MC board connector marked with FAN1;

As shown in Figure 2-4-2, install the air duct under the chamber temperature regulator fan, and lock in 3 screws B to fix it.

|

|

¶ Step 5: Install the Excess chute

As shown in Figure 2-5-1, install the excess chute to the printer, the buckles on both sides of the chute should slide into place, and confirm that the connecting cables are not pressed;

As shown in Figure 2-5-2, lock 1 screw E on the left side of the chute;

As shown in Figure 2-5-3, lock 2 screws D on the top of the chute.

|

|

|

¶ Step 6: Install the Rear Panel

As shown in Figure 2-6-1, first pass the tube bracket through the rear panel, and then install the part near the tensioner on the right side in place, you can the hex key to press the edge to install it;

As shown in Figure 2-6-2, pull the rear panel to the left and install the part near the left tensioner in place, you can use the hex key to press the edge to assist in the installation;

As shown in Figure 2-6-3, lock in 9 screws A, 4 screws B, and 1 screw C to fix the rear panel.

|

|

|

¶ Step 7: Install the Activated Carbon Air Filter

As shown in Figure 2-7-1 and Figure 2-7-2, install the activated carbon air filter to the printer, with the white belts of the filter facing to you;

As shown in Figure 2-7-3, place back the filter cover.

|

|

|

¶ Verify the functionality

1. Connect the AMS to the printer, and start up the printer, confirm that the printer and AMS can start normally;

2. Operate on the screen, click the chamber temperature regulator fan icon, then turn on the fan, confirm that the fan can be turned on and off normally;

3. Operate on the screen, tap the chamber temperature icon, set the temperature higher than the current one, and confirm that the cooling fan of the power supply and the heater fan can start to work.

If the test fails, please check all connections again and try again. If that still doesn't work, please contact the Bambu Lab service team.

¶ Calibration step after the operation

There is no need to perform any calibration or operation before using the printer after the related parts replacement on this page.

¶ End Notes

We hope that the detailed guide we shared with you was helpful and informative.

We want to ensure that you can perform it safely and effectively. If you have any concerns or questions regarding the process described in this article, we encourage you to reach out to our friendly customer service team before starting the operation. Our team is always ready to help you and answer any questions you may have.

Click here to open a new ticket in our Support Page.

We will do our best to respond promptly and provide you with the assistance you need.