Please visit YouTube to watch our full assembly video. Watch the video on the YouTube channel.

¶ Step 1: Unboxing and Removal

- Carefully open the cardboard box

- Remove the foam insert.

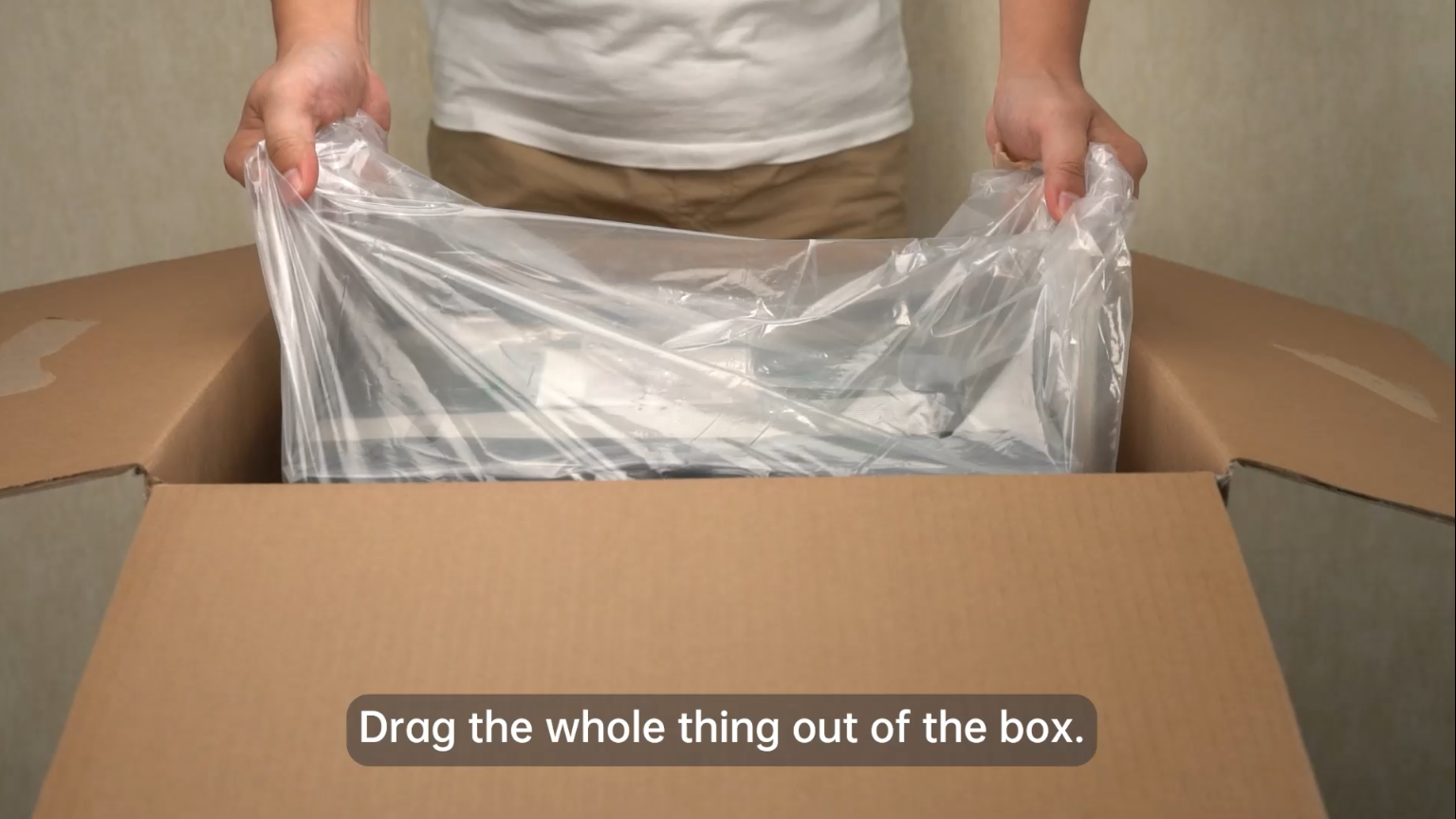

- Drag the whole thing out of the box using the two plastic handles and place it on a flat surface (Note: The printer weighs approximately 12.59 kg.)

- Remove the plastic bag

|

|

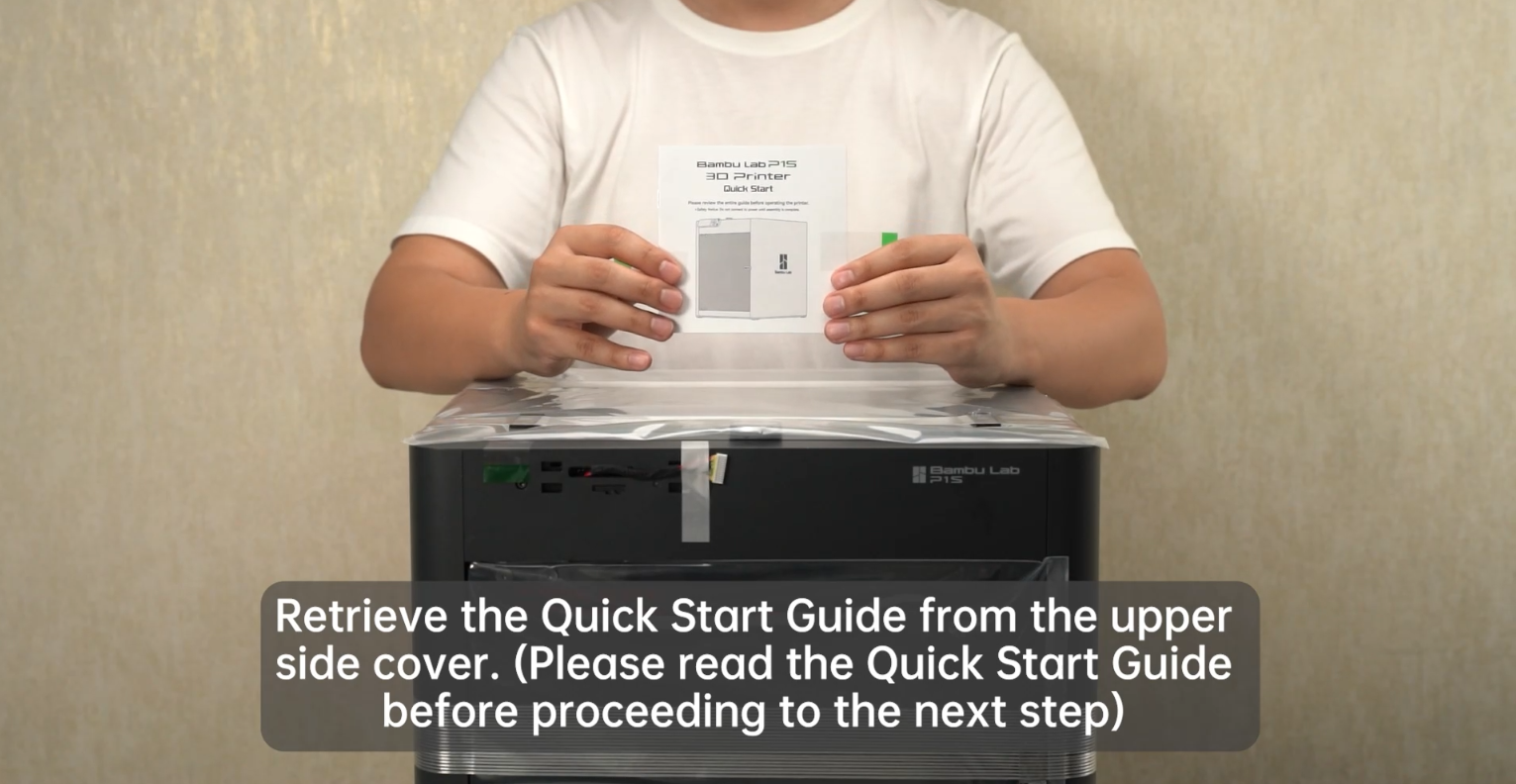

- Retrieve the Quick Start Guide from the upper side cover(Please read the Quick Start guide before proceeding to the next step)

- Carefully remove all the plastic wrappers on the panels

- Remove the foam inserts and take out the accessory box

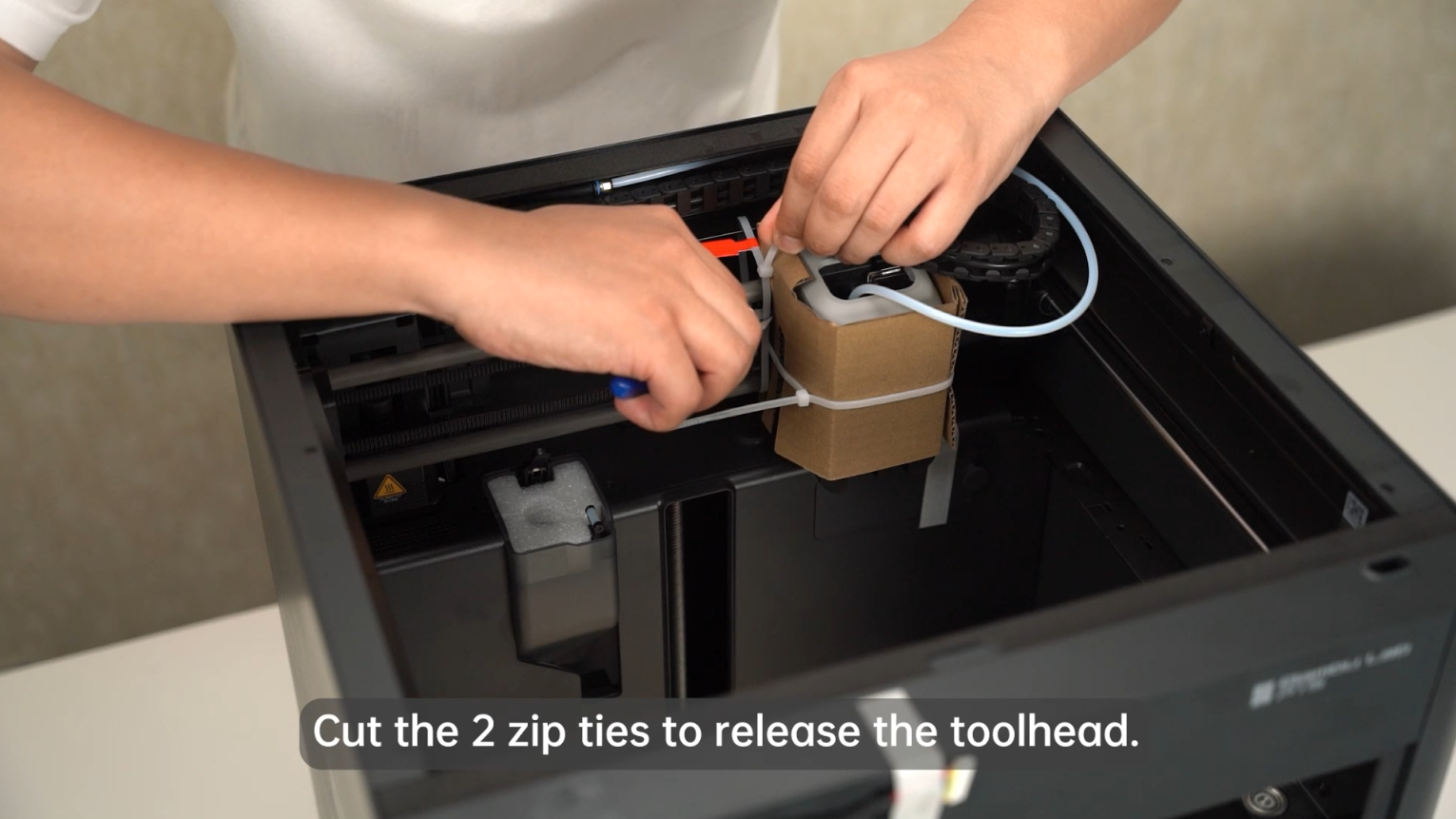

- Cut the two zip ties to release the tool head

- Peal out all the remaining protection tapes

|

|

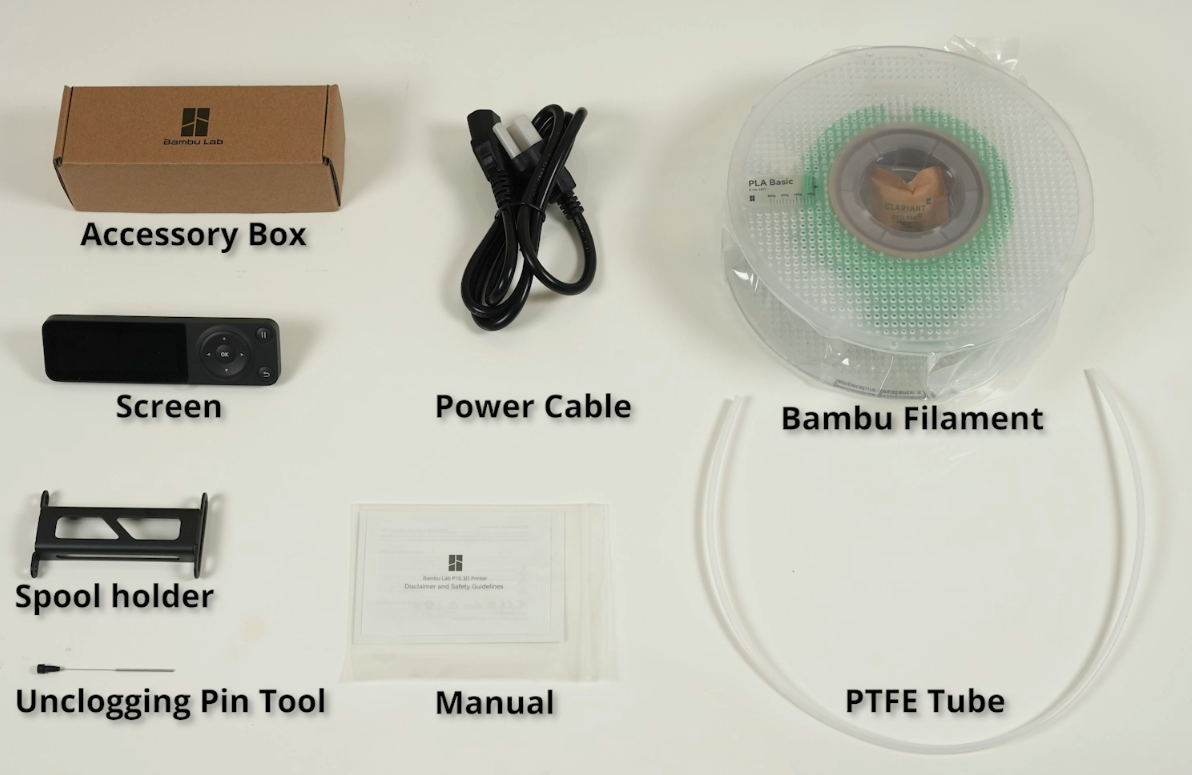

¶ Step 2: Open the accessory box and check the accessories in the box

The P1S package comes with a Screen, Spool Holder, Filament, Spare Hotend, Nozzle Wiping Pads, Power Cord, Unclogging Pin Tool, PTFE Tube, Bambu Scraper, Allen Keys, hotend clip, double-sided tape, 32 GB MicroSD card (inside printer), and Textured PEI Plate (Pre-installed on the heat bed of the printer). Check this page for more detail on the accessory in the box.

|

|

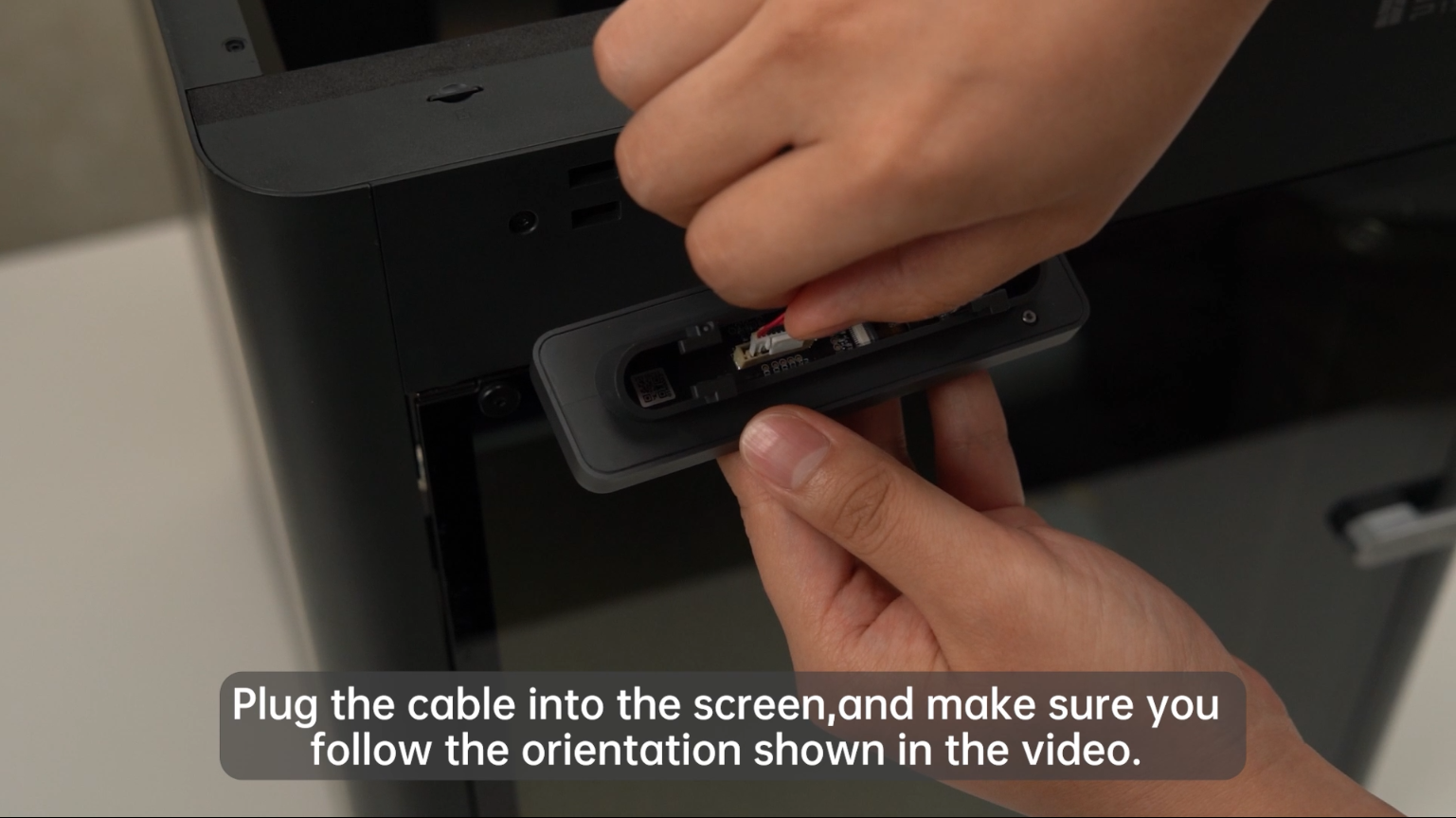

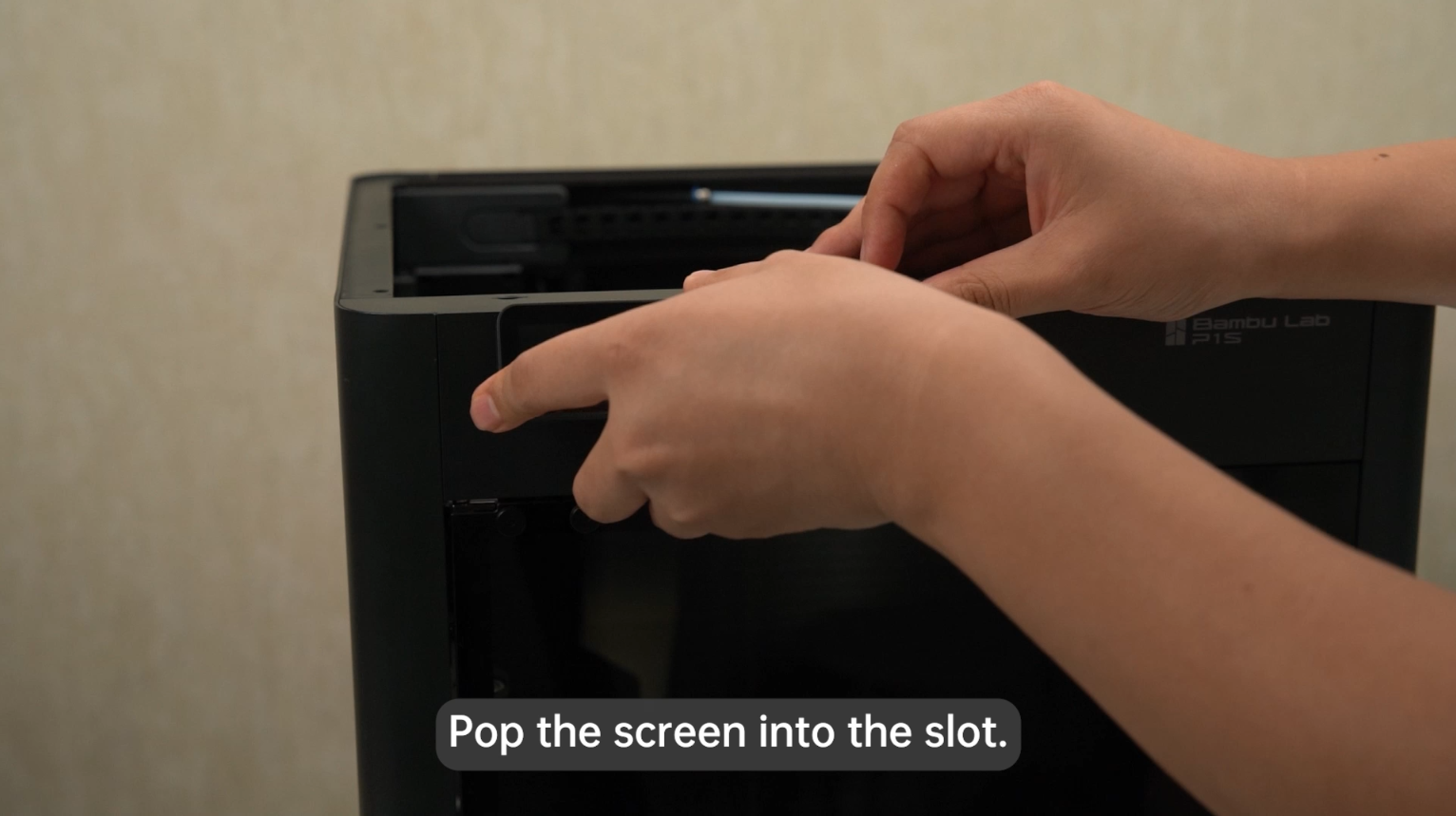

¶ Step 3: Connect the LCD Screen

Plug the cable into the screen, and make sure you follow the orientation shown in the video. Pop the screen into the slot.

|

|

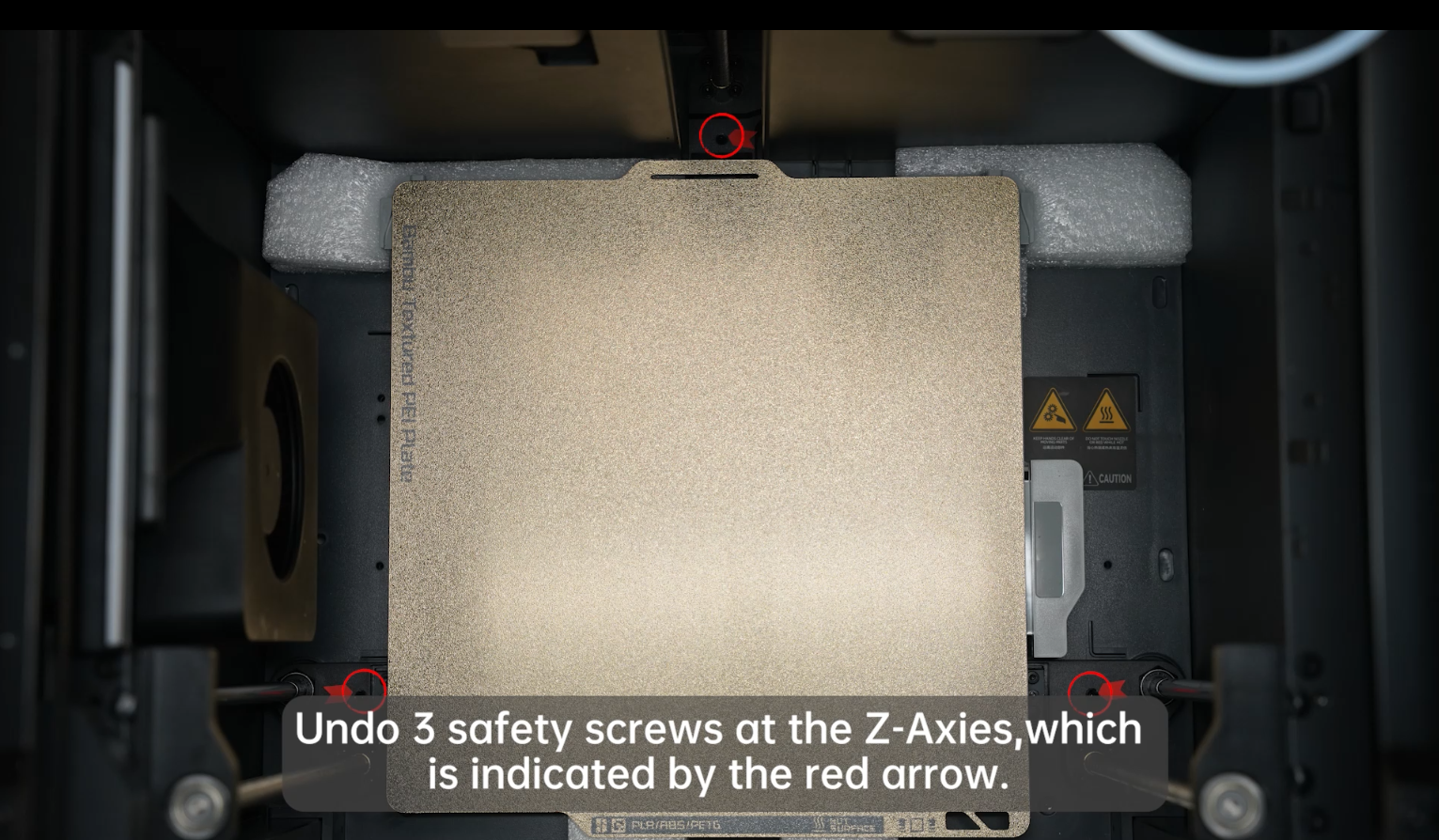

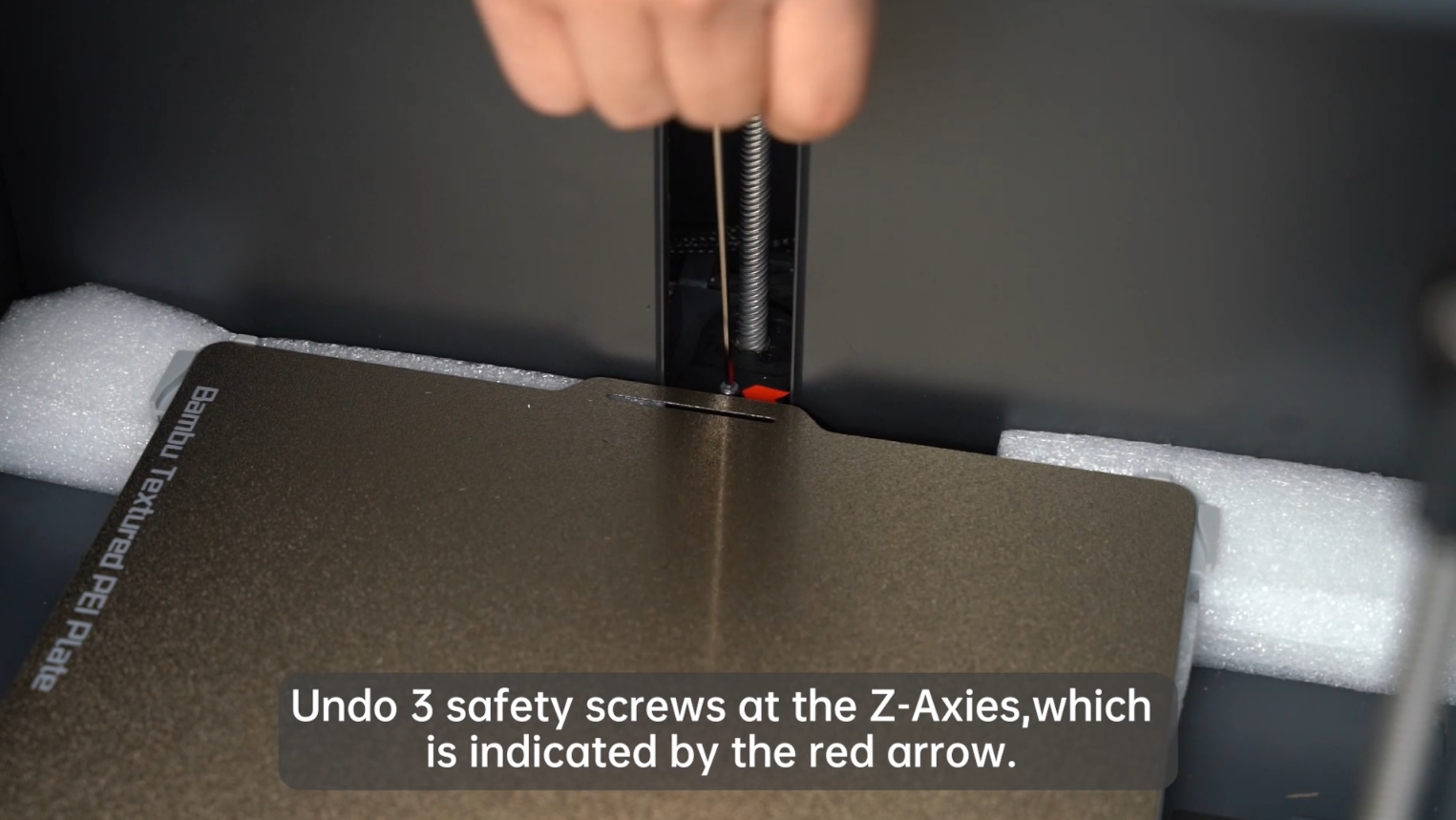

¶ Step 4: Unlock the heatbed

Undo 3 safety screws at the Z-Axies, which is indicated by the red arrow.

|

|

¶ Step 5: Install Spool Holder

- Unscrew the screw from the right screw hole.

- Screw in the Spool holder.

|

|

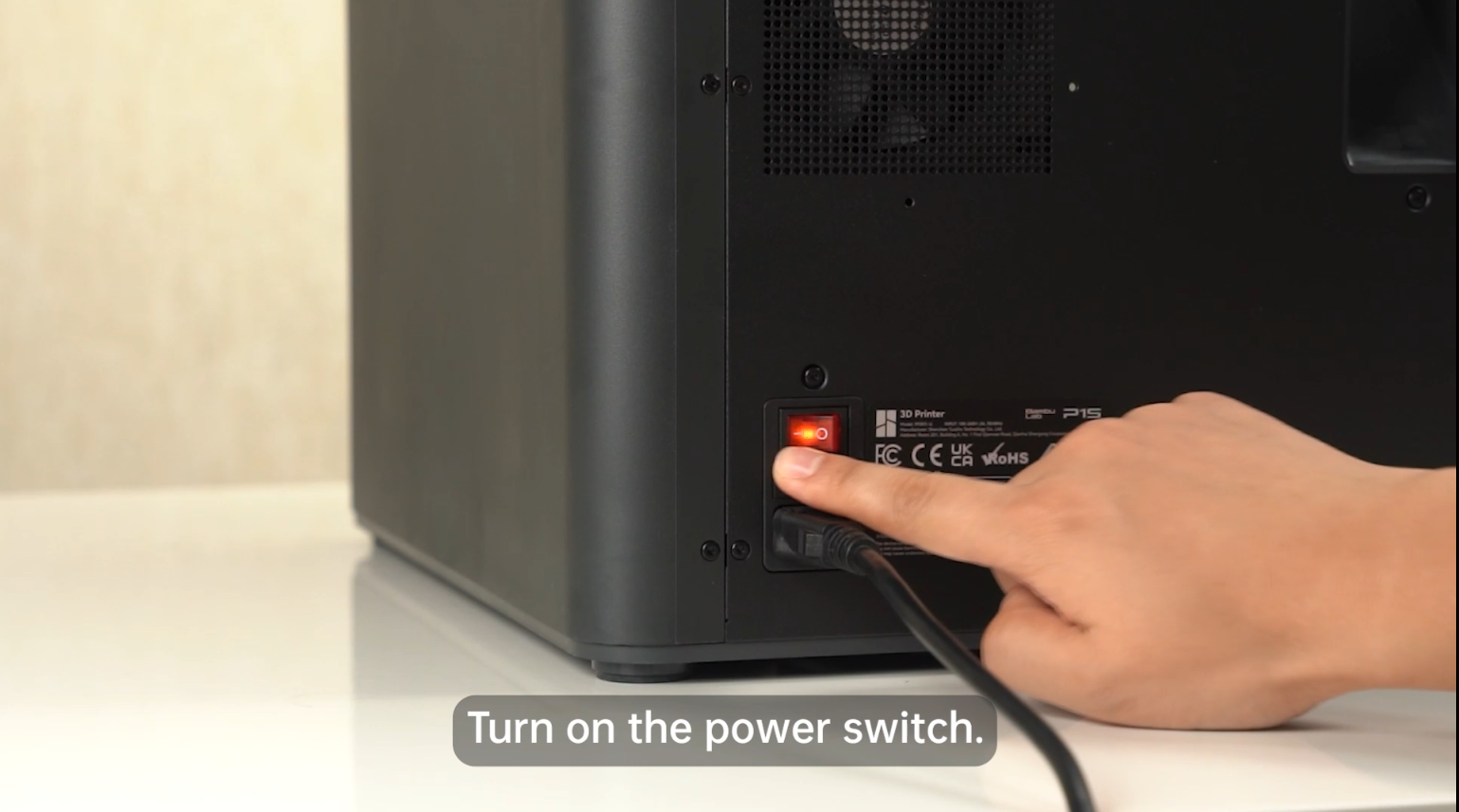

¶ Step 6: Attach the power Cable and start the printer

- Plug in the power cable, turn on the power switch.

- Once the printer is turned on, follow the on-screen guide to complete the printer's self-test. High-Temperature

|

|

¶ Step 7: Remove the foam padding under the heatbed

Once the printer is turned on, follow the on-screen guide to complete the printer's self-test. Don't forget to remove the fixed foam under the heatbed when the self-test is finished.

If you skipped the networking and app binding steps during the unboxing process, please let the printer network and bind the printer in Handy once the self-test is complete.

If you have problems binding the app, please go to this wiki for troubleshooting.

|

|

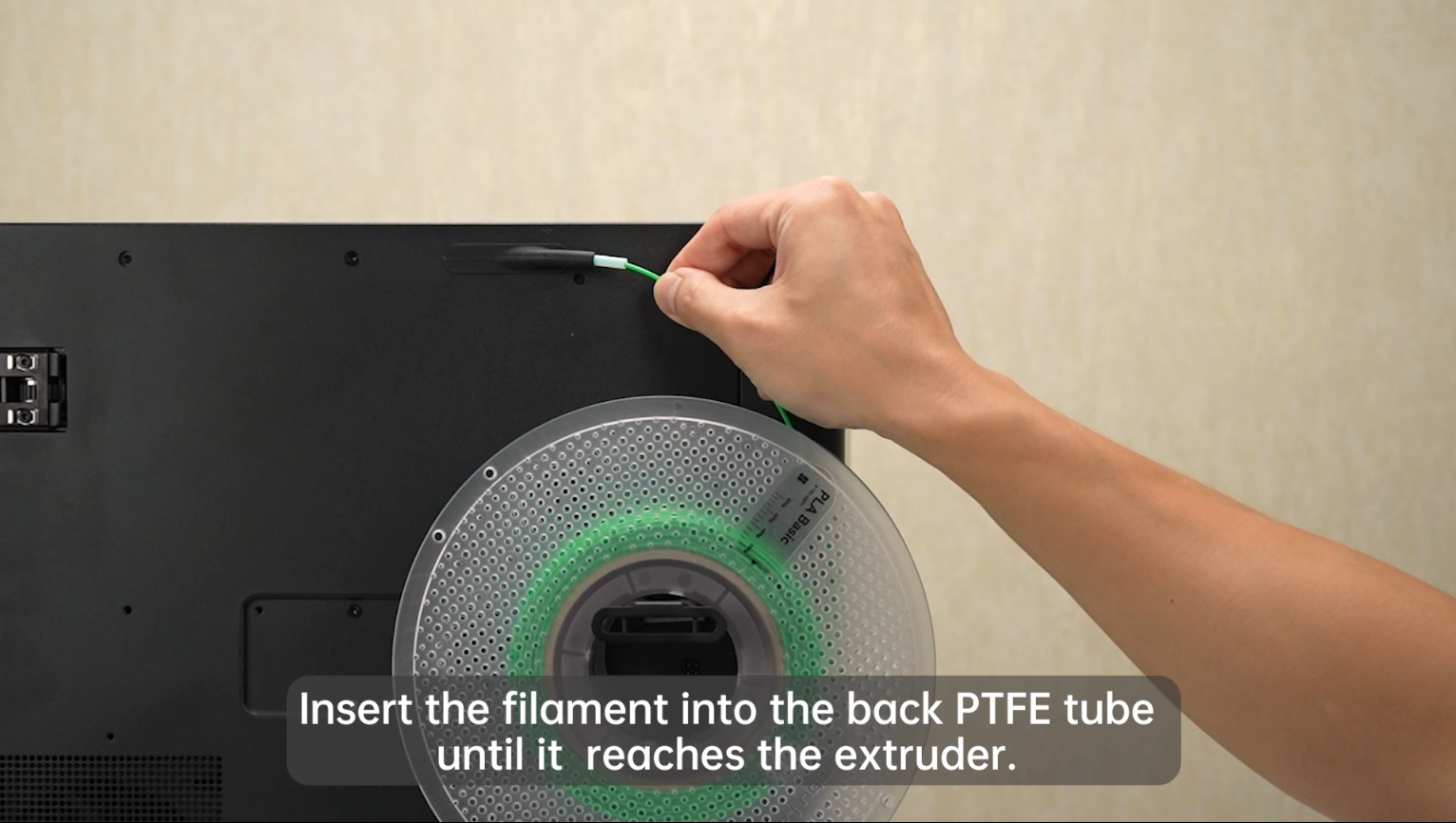

¶ Step 8: Complete the Initialization, and load the filament

Insert the filament into the back PTFE tube until it reaches the extruder. We recommend using the supplied Bambu PLA for your first test print.

|

|

¶ P1S Specifications

| Item | Specification | |

| Printing Technology | Fused Deposition Modeling | |

| Body | Build Volume(W×D×H) | 256*256*256 mm³ |

| Chassis | Steel | |

| Shell | Plastic & Glass | |

| Tool Head | Hot End | All-Metal |

| Extruder Gears | Steel | |

| Nozzle | Stainless Steel | |

| Max Hot End Temperature | 300 ℃ | |

| Nozzle Diameter (Included) | 0.4 mm | |

| Nozzle Diameter (Optional) | 0.2 mm, 0.6 mm, 0.8 mm | |

| Filament Cutter | Yes | |

| Filament Diameter | 1.75 mm | |

| Hot Bed | Compatible Build Plate | Bambu Textured PEI Plate Bambu Cool Plate Bambu Engineering Plate Bambu High Temperature Plate |

| Max Build Plate Temperature | 100 ℃ | |

| Speed | Max Speed of Tool Head | 500 mm/s |

| Max Acceleration of Tool Head | 20 m/s² | |

| Max Hot End Flow | 32 mm³/s @ABS(Model: 150*150mm single wall; Material: Bambu ABS; Temperature: 280℃) | |

| Cooling | Part Cooling Fan | Closed Loop Control |

| Hot End Fan | Closed Loop Control | |

| Control Board Fan | Closed Loop Control | |

| Chamber Temperature Regulator Fan | Closed Loop Control | |

| Auxiliary Part Cooling Fan | Closed Loop Control | |

| Air Filter | Activated Carbon Filter | |

| Supported Filament | PLA, PETG, TPU, ABS, ASA, PA, PC, PVA, PET | Ideal |

| Carbon/Glass Fiber Reinforced Polymer | Not Recommended | |

| Sensors | Chamber Monitoring Camera | Low Rate Camera 1280 x 720 / 0.5fps Timelapse Supported |

| Filament Run Out Sensor | Yes | |

| Filament Odometry | Optional with AMS | |

| Power Loss Recover | Yes | |

| Physical Dimensions | Dimensions(W×D×H) | 389*389*457mm³ |

| Net Weight | 12.95kg | |

| Electrical Parameters | Input Voltage | 100-240 VAC, 50/60 Hz |

| Max Power | 1000W@220V, 350W@110V | |

| USB Output Power | 5V/1.5A | |

| Electronics | Display | 2.7-inch 192x64 Screen |

| Connectivity | Wi-Fi, Bluetooth, Bambu-Bus | |

| Storage | Micro SD Card | |

| Control Interface | Button, APP, PC Application | |

| Motion Controller | Dual-Core Cortex M4 | |

| Software | Slicer | Bambu Studio Support third party slicers which export standard G-code such as Superslicer, Prusaslicer and Cura, but certain advanced features may not be supported. |

| Slicer Supported OS | MacOS, Windows | |

| Wifi | Frequency Range | 2412MHz-2472MHz(CE) 2412MHz-2462MHz(FCC) 2400MHz-2483.5MHz(SRRC) |

| Transmitter Power(EIRP) | ≤21.5dBm(FCC) ≤20dBm(CE/SRRC) |

|

| Protocol | IEEE802.11 b/g/n | |

| Bluetooth | Frequency Band | 2402MHz-2480MHz(CE/FCC) 2400MHz-2483.5MHz(SRRC) |

| Transmitter Power(EIRP) | ≤20dBm(FCC/SRRC) <10dBm(CE) |

|

| Protocol | BLE5.0 | |