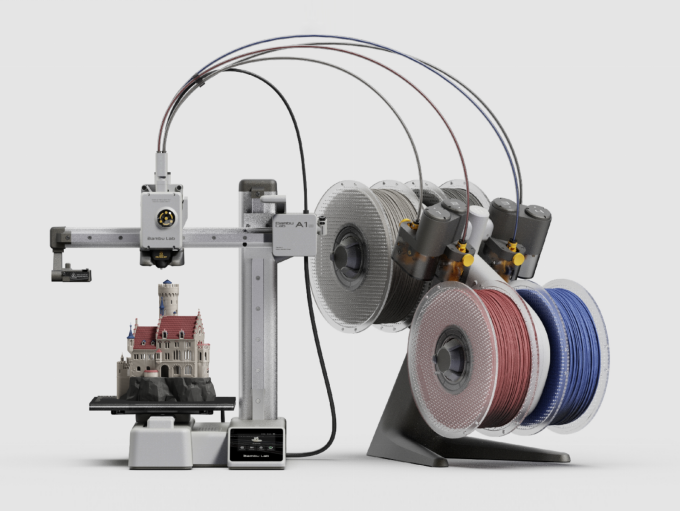

AMS, short for Automated Material System, collaborates with 3D printers to accomplish automated multi-color printing. AMS lite is one variant of the Automated Material Systems developed by Bambu Lab. This article aims to outline the modules, primary functions, and workflow of AMS lite.

¶ Precautions before use

1. The A1 series printers can be connected to a single AMS lite, limiting its support to a maximum of 4-color printing.

2. AMS lite is unsuitable for use with X1 and P1 series printers, and the A1 series printer is not compatible with other versions of AMS.

3. The PTFE tubes connected to AMS lite come in two sizes. The standard length for slots 1/2 is 580mm, and for slots 3/4, it is 700mm. Ensure correct installation to prevent tube misalignment.

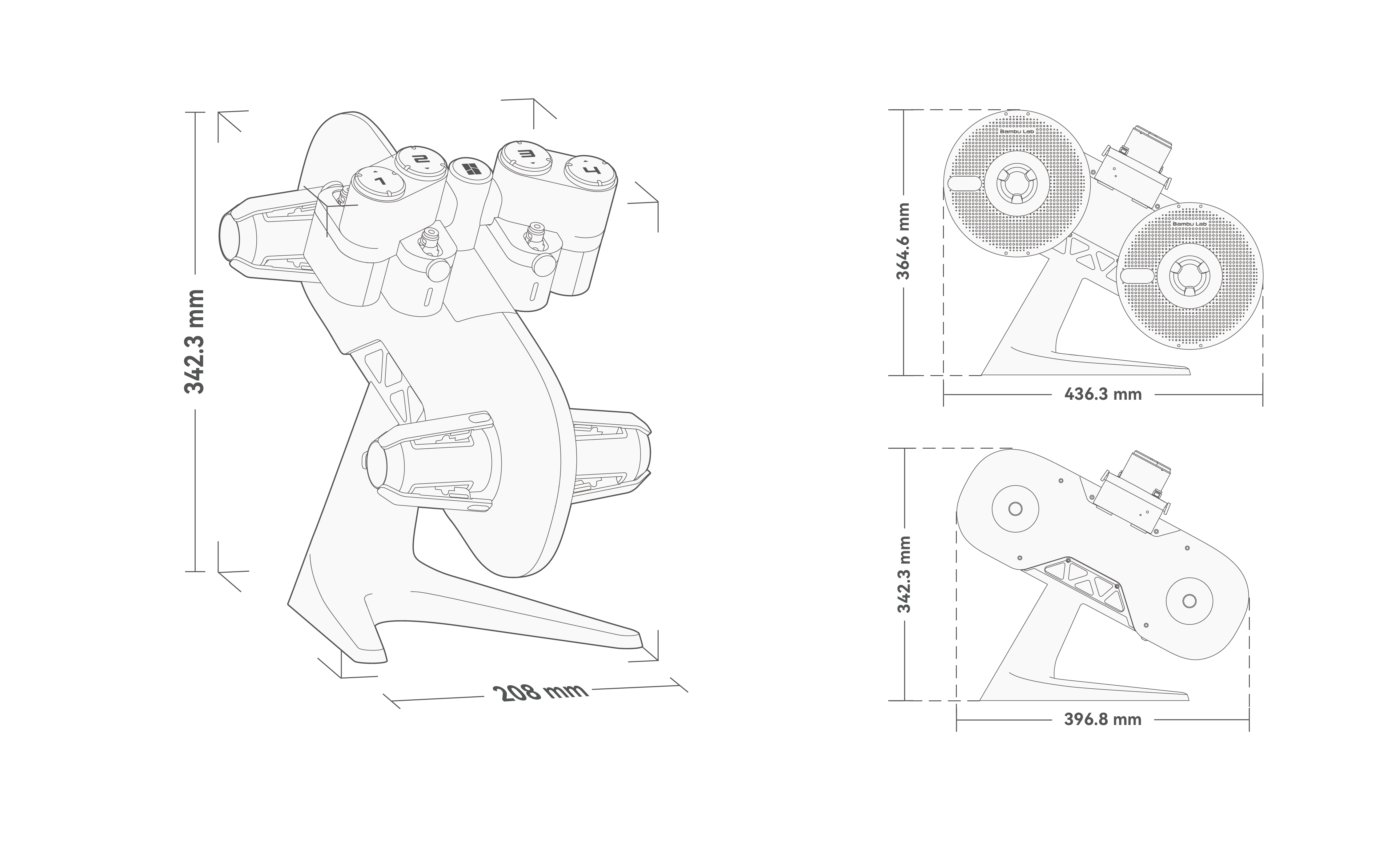

4. Exercise caution not to position the AMS too distant from the printer (the recommended distance is 50mm, as depicted above). Excessive bending of the PTFE tube may lead to heightened feeding resistance, potentially resulting in feeding failures (as illustrated below).

5. The feeder has a maximum feeding distance of 1.2m. Therefore, when replacing a PTFE tube with a longer one, ensure to consider this limitation accordingly.

6. When positioning spools on AMS lite, be mindful of the suitable weight distribution in each slot to avert potential collapse during printing caused by an unstable center of gravity. For enhanced stability, consider placing heavier spools in the lower two slots (slots 2 and 3) where the center of gravity is lower.

¶ AMS lite feeding system

From AMS lite to the printer, the entire feed system is divided into the following two parts:

1. AMS lite: First stage feeder + Rotary Spool Holder. Each slot has a feeder and a rotary spool holder

2. Tool head:Filament tangle detection module + Extruder + Hotend

¶ First stage feeder

Each slot in AMS lite is equipped with a feeder responsible for feeding the filament into or out of the tool head. The feeder includes a filament detection sensor, as depicted below:

Each feeder is equipped with an odometer featuring a passive wheel. The odometer wheel rotates solely when it seizes the filament with another gear to dispense it. This mechanism allows for verifying if the filament has been extruded from AMS lite and facilitates the calculation of the length of the dispensed filament.

Moreover, each feeder incorporates a speed sensor positioned at the base of the DC motor. The speed sensor calculates the motor speed (v1), while the speedometer sensor computes the speed (v2). Analyzing the disparity between v1 and v2 enables the identification of potential filament slipping during the feeding process.

¶ Rotary Spool Holder

Each slot in the AMS lite has a rotary spool holder for placing the spool. Each rotary holder can automatically turn a certain Angle. When unloading, the feeder will pull filament out of the extruder, the rotary holder will automatically turn a little, ensuring that the filament roll on the spool are tightened and maintain the tension. The maximum Angle of auto rotation is 150°, so it can not roll back too long filament.

¶ Filament tangle detection module

The tangle detection module above the tool head consists of a filament Hub and a feed bracket. The PTFE tubes corresponding to each slot of the AMS lite are connected to the filament hub, which holds the four tubes together. The side of the feed bracket is a small board, and it also has a spring inside, and there is a magnet under the filament hub, when the filament hub and the feed bracket are assembled together, they form a filament tangle detection module. When the feed resistance is too high, the tangle detection module will be pressed down, and the magnet will move closer to the Hall sensor and trigger the alarm.

Please refer to the Wiki Introduction to filament tangle monitoring

¶ AMS Lite Functions

¶ Pre-loading

When AMS lite is idle, insert the filament into the feeder, the feeder will feed the filament into the PTFE tube about 40cm, this process is pre-loading.

¶ Reading RFID

Each slot in AMS lite has a corresponding RFID coil. You just need to place the spool on the rotary holder of each slot and insert the filament to read its information.

RFID reading function can be set on the slicer for update on insertion/startup, or you can also manually click the icon beside each slot on the slicer for reading RFID.

¶ Customize filament information

When using a third-party filament, it is possible to manually edit its properties.

¶ Automatic mapping function

When you send a multi-color print task in the slicer, the model is automatically matched to the closest color filament in the AMS slots. You can also customize the filaments in the window.

If you want to know mor about multi-color, please refer to Multi-color printing operation guide.

¶ Filament run-out detection and filament backup function

When you use AMS printing, it still has the filament run-out detection function, which can be divided into the following two cases:

1. Single material printing: When the tool head detects that the filament runs out, it will first check whether the feeder's Hall switch still detect the filament. If the feeder detects the filament, the tool head will move to the purge wiper, and the feeder will continue to feed the filmanet to the extruder without reporting any error. If the feeder's Hall switch also does not detect the filament, it will report that the filament runs out and a new filament needs to be inserted.

2. Multi-material printing: There is a special case of multi-material printing, that is, the last section of filament has been detached from the spool. At this time if the filament needs to be switched in the middle of printing, as the filament can no longer be pulled back, it will directly flush the remaining filament, and then switch to another slot of filament to continue printing after the flushing is completed. The screen will indicate that the filament has run out, please wait while the old filament is purged.

3. AMS filament backup: the AMS lite will switch to another spool with the same filament properties automatically when the current filament runs out. These filament properties include brand, type, color, and nozzle temperature. If the AMS cannot find the same filament, it will display a prompt that the current slot has run out. To enable this feature, please check "AMS filament backup" on the AMS settings page.This function requires filaments with exactly the same properties. It is recommended that Bambu filament be used as a replacement for Bambu filament and non-Bambu filament be used as a replacement for non-Bambu filament.

¶ AMS Workflow

¶ Loading & Unloading

During the loading process, the feeder advances the filament into the tool head and ceases operation after the extruder gear grips the filament for 3mm. As the extruder proceeds to extrude the filament, successful loading and filament grab are confirmed if the corresponding odometer wheel for the feeder also rotates.

During the unloading process, the extruder sends out the filament, and the feeder pulls back the filament out of the filament Hub, it is considered that the unloading is successful.

¶ Check Filament location

When you click load/unload or start printing, if there is a filament inside the tool head, it will check the filament location. The purpose of this check is to see if the filament inside the tool head is coming from which slot in the AMS or from the external spool.

For each slot, only one feed sensor, specifically the feed Hall sensor, is present. When all four slots have filaments inserted, AMS cannot determine which slot the filament is dispensed from based on the sensors alone. For instance, if filament from slot 1 is loaded, the screen/Studio will display in bold that filament from slot 1 is connected to the tool head, indicating its presence (as illustrated below).

However, if you cut off the filament from the tool head and pulls it out, and feeds the filament in slot 2 manually, the screen still shows that the filament in slot 1 is connected to the tool head. So it is necessary to check the location of the filament once to know which slot the current filament is from before loading/unloading.

Filament location check logic: When there is a filament inside the tool head, it will try to extrude a small section. If the odometer wheel of the feeder in which slot moves, the filament is coming from this slot. If it can not extrude the filament, each slot will try to pull back a small section of filament, if the sensor of the tool head detects no filament after pulling back the filament in which slot, it indicates that the filament is from this slot. If the above two methods do not find the slot of the filament, it is judged that it is from the external spool or it's a broken filament.

¶ Printing

After AMS lite successfully feeds the filament to the extruder and starts printing, only the extruder pulls the filament during the printing process, and the feeder motor of AMS lite does not work. So at this time the motor inside the feeder is not rotating, and the odometer wheel will still rotate.