¶ What is the recommended ambient temperature and humidity for the AMS lite?

The recommended ambient temperature of the AMS lite is 10℃ - 30℃ (50°F - 86°F). The recommended humidity level is under 85%.

¶

¶ How many AMS lites can a printer connect to at most?

A1 series printers can only be connected to one AMS lite for use.

¶ If I want to use the AMS lite included in the A1 mini combo, how should I adjust the length of the PTFE tube for optimal performance? If the current tube length is unsuitable, can I purchase PTFE tubes of the appropriate length?

The provided PTFE tube in the A1 Mini combo is not of sufficient length for direct compatibility with the A1. If necessary, you can acquire appropriate PTFE tubes for the A1 from the official store, such as 730mm * 2 and 850mm * 2. Alternatively, you have the option to purchase a 4000mm PTFE tube and cut it into two segments, each measuring 730mm, and two segments, each measuring 850mm.

¶ As for the AMS lite unit (not included in the combo), is the length of the PTFE tube compatible with both the A1 mini and the A1?

The length of the PTFE tubes included with the AMS Lite unit corresponds to the dimensions of the A1 combo, specifically 730mm * 2 and 850mm * 2. However, for the A1 Mini combo, the PTFE tube specifications are 580mm * 2 and 700mm * 2. If you intend to use the AMS Lite with the A1 Mini, it is advisable to adjust the position of the tubes or cut them shorter. Excessively long tubing can elevate resistance during loading and unloading, potentially leading to false filament entanglement detection alarms.

¶ What are the requirements for the filament compatible with AMS lite?

The AMS lite supports spools with a width of 40-68 mm and an inner diameter of 53-58 mm.

Avoid using AMS lite to print flexible materials, including TPU (see below for more details), TPE, or absorbent PVA.

Avoid using materials that are too hard (too high modulus) or too brittle (not enough toughness), including third-party fiber reinforcement materials (PET-CF/GF, PLA-CF/GF, etc.). Please use external spool placement to print these filaments.

TPU that can be used with AMS lite: 77D, 55D, or higher hardness.

TPU that cannot be used with AMS lite: 95A, 85A, 83A, 80A, or lower hardness.

¶ Is CF filament OKAY to print using AMS lite?

Due to their excessive brittleness, hardness, or roughness, CF (Carbon Fiber) and GF (Glass Fiber) filaments are prone to breakage inside the AMS lite feeder channel or may cause damage to the channel. Therefore, it is not recommended to use CF and GF filaments with AMS lite. However, CF and GF filaments with improved durability and relatively smoother surfaces, such as Bambu PLA-CF and Bambu PETG-CF, are compatible with AMS lite.

¶ Can I use AMS lite on an X1 or P1 printer?

AMS lite is incompatible with the X1 or P1 Series printer. If you want a multi-color print using an X1 or P1 Series printer, you must use AMS.

¶ Are there any precautions to take when using AMS lite? And what size of inner diameter spools work best for the AMS lite?

To ensure optimal performance and avoid potential issues, refrain from using AMS Lite to print flexible materials such as TPU, TPE, or absorbent PVA. Similarly, avoid using materials that are excessively hard (with a high modulus) or too brittle (lacking toughness), including third-party fiber reinforcement materials like PA-CF/GF, PET-CF/GF, PLA-CF/GF, PLA Glow, etc. For these filaments, it is recommended to use external spool placement. AMS Lite supports spools with a width of 40-68 mm and an inner diameter of 53-58 mm.

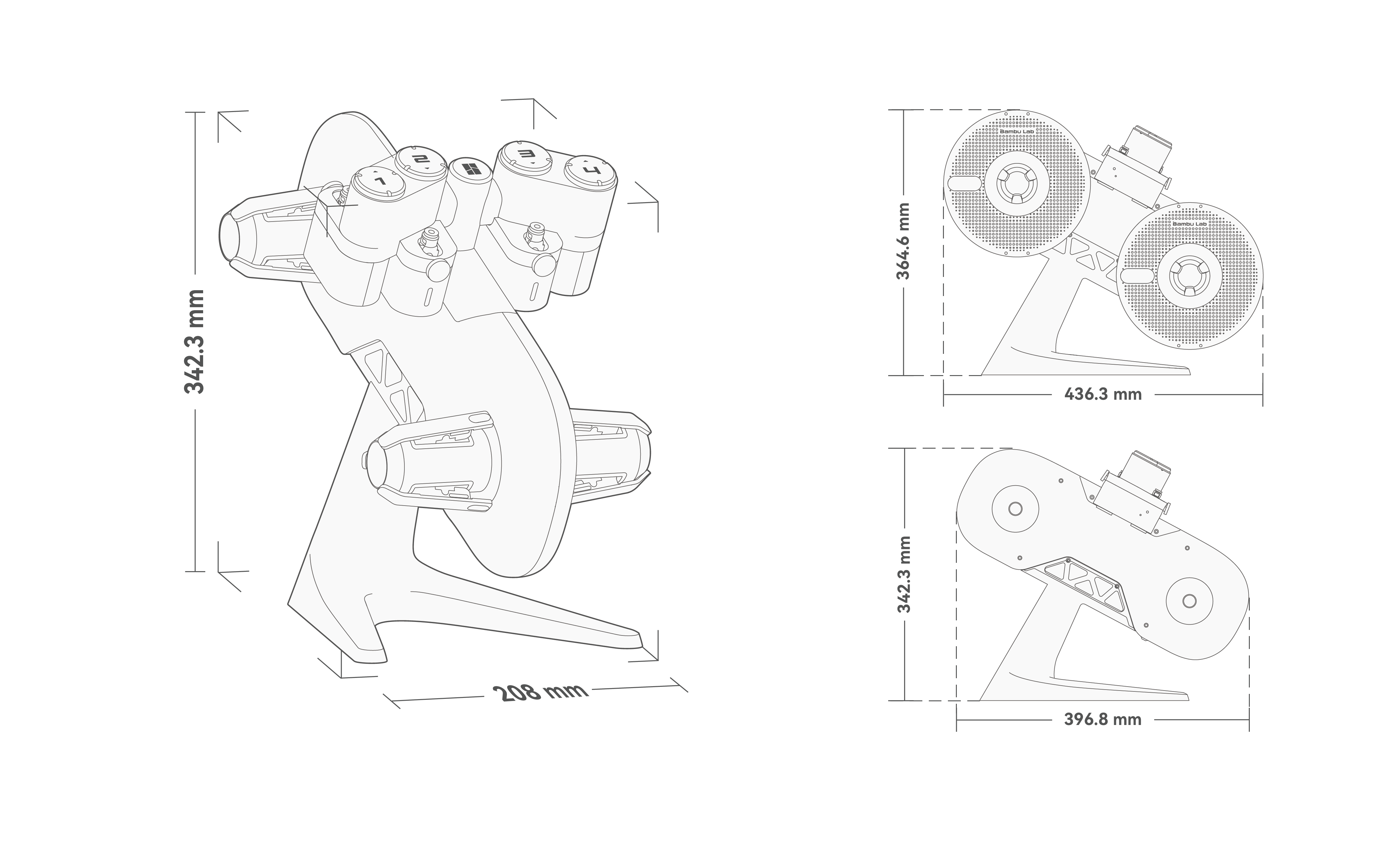

¶ What is the size occupied by AMS Lite?

Please refer to the following diagram:

¶ How can I prevent the AMS lite from vibrating or moving due to vibrations while printing?

To enhance stability and prevent shaking or movement during printing, it is recommended to place the heavier spool in the 2/3 slot and the lighter spool in the 1/4 slot. This arrangement ensures that the AMS Lite maintains a lower and more stable center of gravity.

¶ Can the AMS lite be wall-mounted?

No, the AMS lite can not be wall-mounted. To minimize resistance during filament loading and unloading, it is recommended to position the AMS Lite according to the diagram below.

¶ Does the AMS lite support filament spool backup?

Yes, AMS lite will automatically switch to another spool with the same filament properties when the current filament runs out.

¶ How to install AMS lite on top of A1?

Please refer to the Wiki AMS lite Top Mount guide.

¶ End Notes

We hope that the detailed guide we shared with you was helpful and informative.

We want to ensure that you can perform it safely and effectively. If you have any concerns or questions regarding the process described in this article, we encourage you to reach out to our friendly customer service team before starting the operation. Our team is always ready to help you and answer any questions you may have.

Click here to open a new ticket in our Support Page.

We will do our best to respond promptly and provide you with the assistance you need.