The heatbed of the Bambu Lab A1 is calibrated before leaving the factory. Once you have followed the instructions in the Quick Start guide, you can start printing directly. However, in cases where the heatbed is affected during transportation, resulting in auto-leveling failure, or if the heatbed needs to be disassembled or replaced for maintenance purposes, it is important to ensure that the heatbed is flat using the bed tramming method.

¶ Prepare for Bed Tramming

Before starting the bed tramming procedure, it's important to prepare the printer.

1. Remove the hotend sock and ensure that the nozzle is clean and free from any filament on the tip. If needed, heat up the nozzle and wipe the nozzle to ensure it is clean;

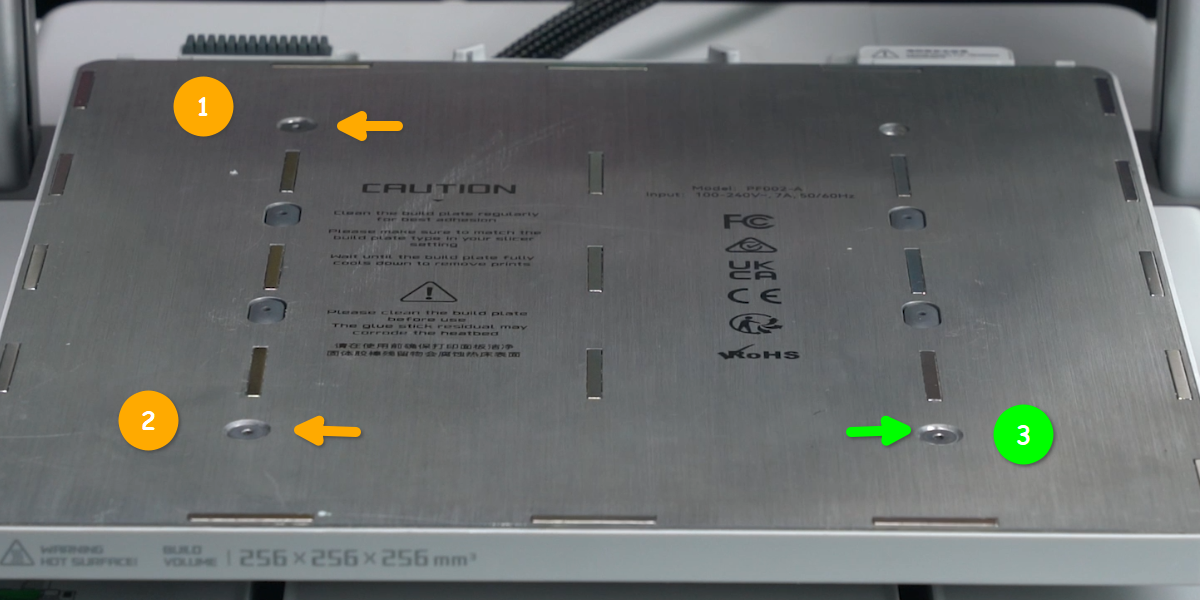

2. Make sure the 2 heatbed locking screws under the heatbed are fully loosened;

3. Remove the build plate and clean the surface of the heatbed, then tighten the 3 heatbed leveling screws one turn or until the bottom end of the screws sit flush with the bottom bracket. (You can feel the position with your fingers)

|

|

¶ Start the Bed Tramming

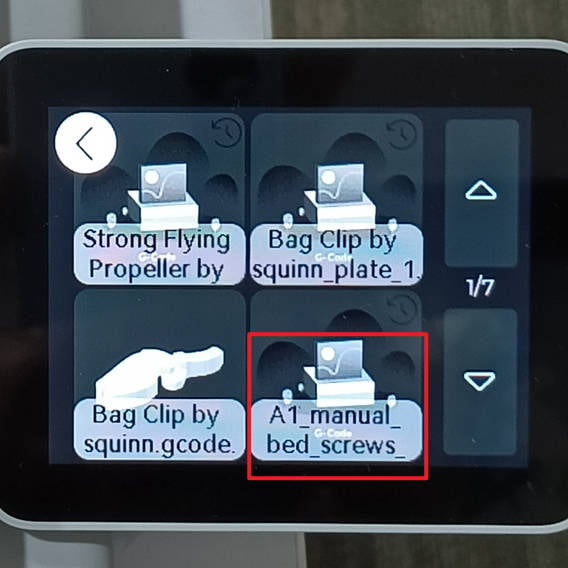

To begin the bed leveling process, first, download the attached g-code file, transfer it to a MicroSD Card, and then power on the printer.

a1_manual_bed_screws_adjust_assist.gcode

After the printer completes the startup and can successfully identify the file, select the above Gcode file and click to run it, just like you would start a new print.

Please note that A1 SD card is not hot-swappable. Please turn off the power before inserting or removing the SD card to avoid any potential damage or corruption.

|

|

After the g-code file is loaded, the printer will home, then move over to the front left corner and wait for 30 seconds. When this happens, carefully turn the corresponding bed leveling screw until the printing surface barely touches the nozzle.

Reminder: Tightening the leveling screws clockwise will increase the distance between the heatbed and the nozzle; conversely, loosening the leveling screws counterclockwise will make the heatbed closer to the nozzle.

Please make sure that the nozzle is just touching the printing surface. The nozzle should not push against the printing surface, and there should be no gap between the nozzle and the bed.

|

|

|

A piece of paper can be placed between the nozzle and the heatbed to detect the distance between the heatbed and the nozzle.

When you find that the nozzle starts to actively lift, be sure to stop the leveling action and remove the hex key because the tool head will start to move.

After 30 seconds, the nozzle will move to the front right corner of the heatbed. Repeat the procedure until the nozzle barely touches the bed. The same will happen on the left rear part of the bed.

When the first leveling is done, the process will be repeated two more times, to allow you to fine-tune the adjustment and double-check the distance between the nozzle and the bed. The entire Gcode running time is about 8 minutes.

Now please tighten the 2 screws that lock the heatbed. The A1 Bed Tramming is completed.

¶ Video

¶ Potential problems and solutions

If you find that you cannot make the printing surface barely touching the nozzle during the adjustment, it is recommended that you perform the following operations:

- Make sure that the two heatbed locking screws on the rightside are in place and loosened;

2. Tighten all the 3 leveling screws clockwise to the end, then loosen the 2 screws on the left counterclockwise for 3 turns, but the 1 screw on the right side counterclockwise for only 1 turn ;

3. Run Gcode again to start the bed tramming.

¶ Calibration

From the printer screen, touch Settings > Maintenance > Calibration to start the calibration. If everything looks good and no errors or warnings appear during the calibration, the leveling was successful. If there are still problems, contact the service team for further assistance.

¶ End Notes

We hope the detailed guide provided has been helpful and informative.

To ensure a safe and effective execution, if you have any concerns or questions about the process described in this article, we recommend submitting a technical ticket regarding your issue.

Please include a picture or video illustrating the problem, as well as any additional information related to your inquiry.