Nozzle clogs are a somewhat common occurrence within the 3D Printing realm, so chances are that at some point you will encounter them. Clogs can happen for a few different reasons, like for example, the temperature of the hotend is not high enough to ensure the plastic melts quickly enough while being extruded, or maybe the filament you use could have microscopic particles (like types of wood filament or other infused filaments) that would gather at the tip of the nozzle restricting the flow. The symptoms are fairly easy to diagnose as these will show themselves through:

- Under extrusion (not enough plastic is being extruded, resulting in gaps around the printed model)

- No extrusion (the printer is doing the right moves, but no filament is coming out of the nozzle)

¶ Tools needed

- Unclogging Pin Tool

- Plier

- Oven glove

¶ Notes before you start

Please note that some of the operations within this guide could be hazardous if not performed with care as they involve high nozzle temperatures. Please take all precautions necessry when performing these tasks. For some of these procedures, the machine should be powered off and the nozzle should be completely cooled down for most of these procedures.

When it is necessary to hold the hotend in your hand, please wear an oven glove and make sure that the floor or tabletop below the hotend is free of flammable materials or furniture or flooring that can be easily damaged by the heat.

¶ Operation guide

We offer the following four ways to unclog your hotend, so you can choose the right method depending on the clogged hotend.

¶ 1. Heating extrusion

This is the easiest way to unclog the nozzle:

¶ Step 1:Heating the hotend

Increase the temperature of the hotend to a temperature slightly higher than that required by the filaments (PLA for example, set the hotend temperature to 250°C);

¶ Step 2:Manually extrude the filament

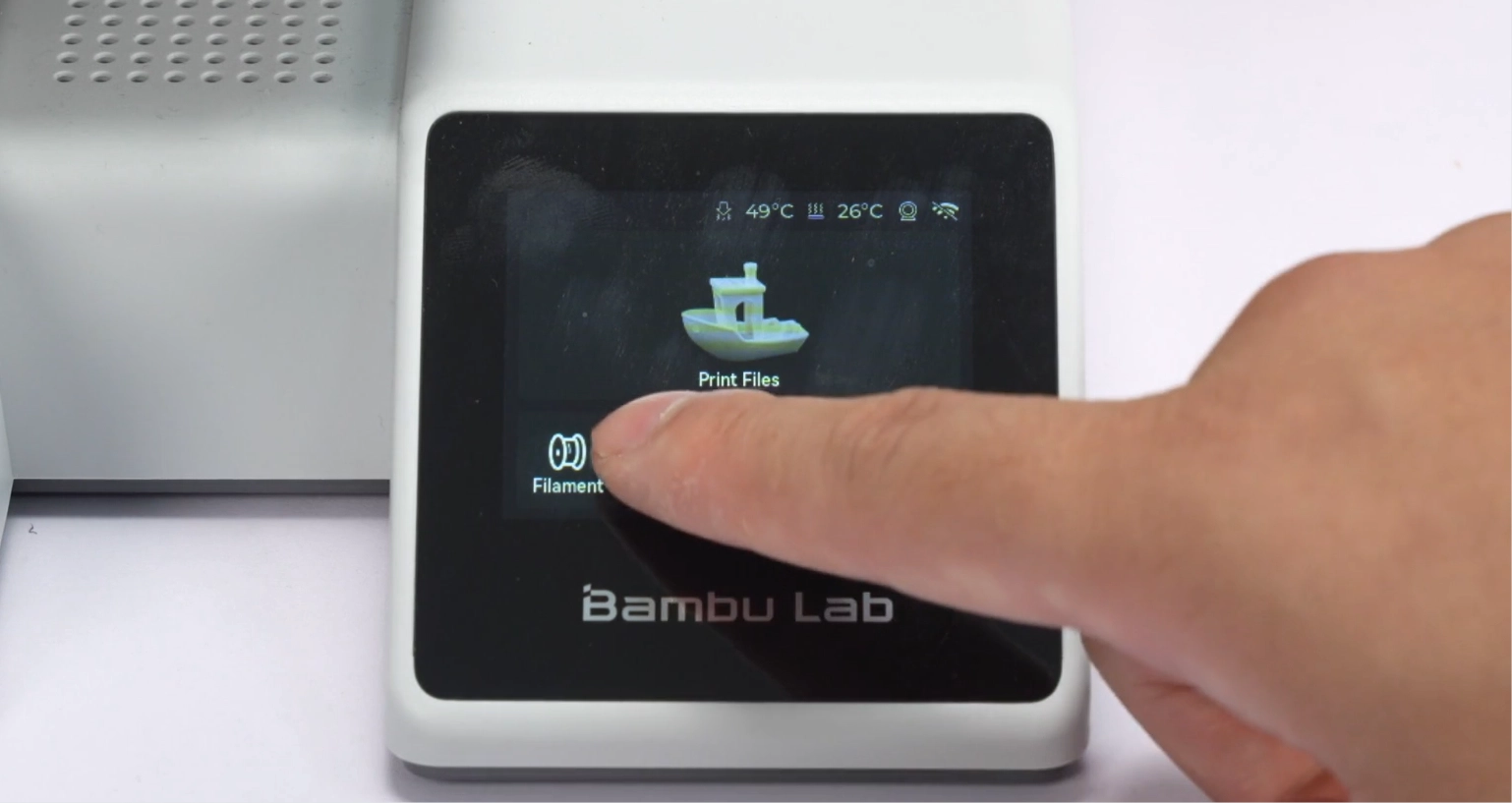

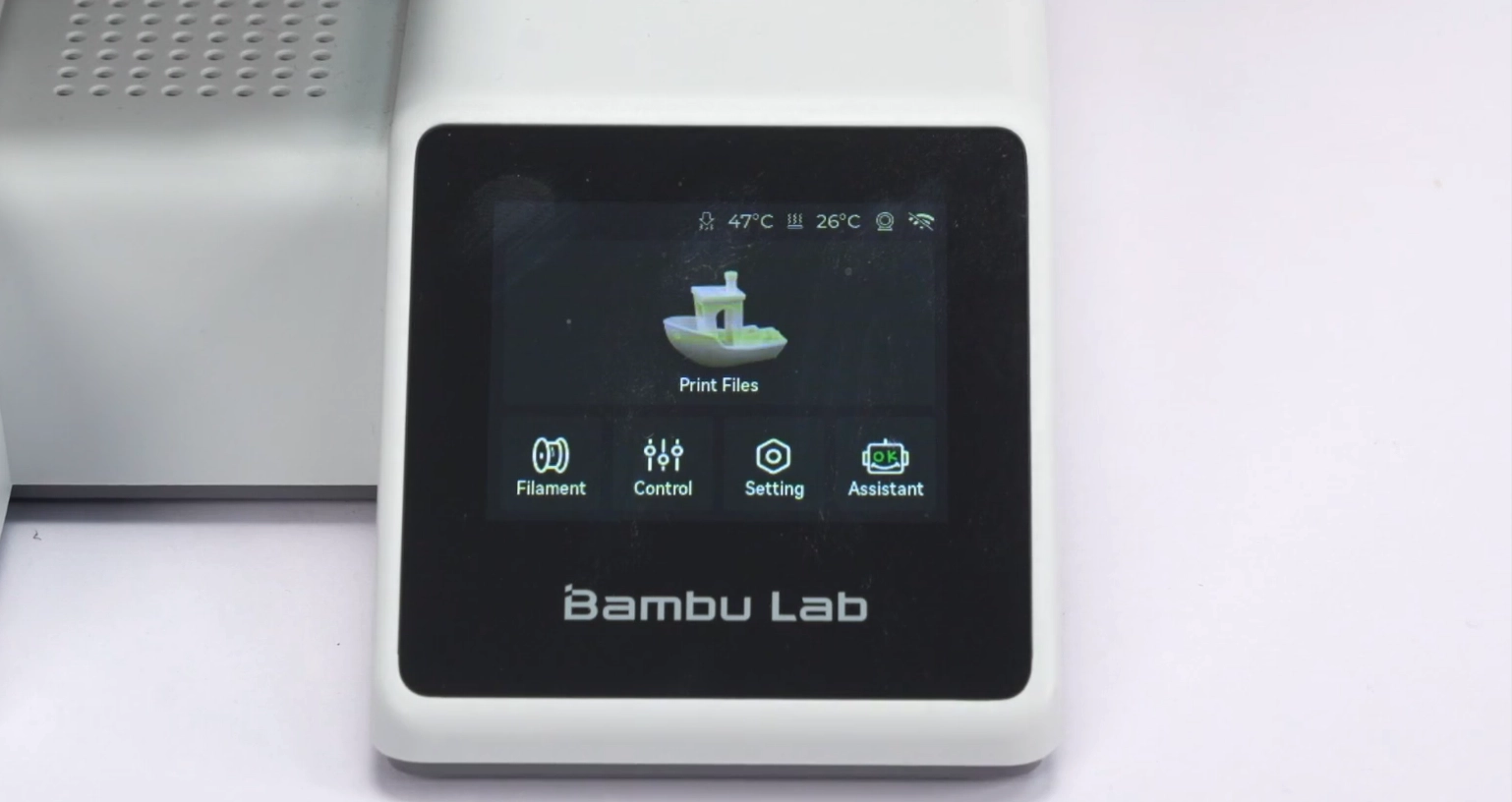

Extruding filaments by clicking the feed button on the screen

¶ 2 Unclogging with a pin tool and cold pull

We have provided a complete video tutorial along with written instructions and images. Here is the complete video of unclogging with a pin tool and cold pull:

¶ Step 1:Preparation before starting

Move the Z-axis to the appropriate height, and also move the tool head to the appropriate height; and remove the front cover of the tool head for the next step

¶ Step 2:Heat the hotend and remove the filament

Heat the hotend to 100°C (PLA for example) and remove the hotend while it is heated (Please operate with oven glove!).

|

|

Remove the filament at the entrance of the hotend with a plier.

¶ Step 3:Placing the hotend and reheat it

Placing the hotend back in, set the hotend temperature to 220°C and load another colour of the same filament;

|

|

¶ Step 4:Manually extrude the filament and cold pull

If the extruded filament from the nozzle becomes completely freshly loaded, the hotend temperature can be lowered to 100°C and cold pull can begin.

|

|

¶ Step 5:Unclogging with a pin tool

If the filament cannot be extruded from the nozzle, or if the filament extruded from the nozzle does not become freshly loaded, it will be necessary to use a through-needle to unclog the hotend and manually re-extrude the filament (cycling the unclogging with a pin tool and extruding process).

¶ Step 6:Reconnect the PTFE tube and test extrusion

Reconnect the PTFE tube and load the filament and test the extrusion. If there is still no extrusion or under extrusion, several more attempts to clear the hotend will be required.

¶ How to verify completion/success

While the above methods tend to clear out 99% of clogs, there might be cases where a nozzle simply needs to be replaced as it could be damaged. If after all these, your machine is printing correctly, then you have successfully unclogged your nozzle.

¶ Note

0.2mm nozzles are much more difficult to clear clogs from and might require the above steps several times over. On the other hand, nozzles larger than 0.4mm tend to clog a lot less than 0.4mm ones as the opening of the nozzle allows for larger particles to go through.

¶ End notes

We hope the detailed guide provided has been helpful and informative.

To ensure a safe and effective execution, if you have any concerns or questions about the process described in this article, we recommend submitting a technical ticket regarding your issue.

Please include a picture or video illustrating the problem, as well as any additional information related to your inquiry.